Woven polypropylene fabric is produced from polyester long fiber forming into net and consolidation with three dimension structure. It’s kind of new material in geotechnical and engineering project. Except for its good mechanical properties of tensile strength and puncture resistance, the woven polypropylene fabric also has good drainage ability, acid and alkali resistance and anti-aging. The wider opening size allows it has good permeability and filtration.The non woven polypropylene fabric has the following advantages:

- Improve the stability of slope and reinforcement soil, avoid water and soil loss and soil frozen injure.

- Isolation layer of artificial backfill soil stone with foundation and different tundra.

- Filtration layer of drainage pipe or gravel sub-drain

- Vertical or horizontal drainage; Bury in soil to release air pressure.

- Reinforce the weak foundation of engineering of road, railway, embankment, airport.

Landfill leakage pollution environmental harm is enormous. Soil contamination and salinization will be poisoned, parasites, pathogenic bacteria and other pathogens in the soil can help the public sick. Penetration will pollution of groundwater, and eventually entered the human food chain, causing serious harm to human body. The landfill anti-seepage treatment project abroad often adopts 1-2mm thickness high density polyethylene geomembrane liner and 200-600gsm polypropylene geotextile, this mature technology is getting more and more attention and becomes the industrial standard.

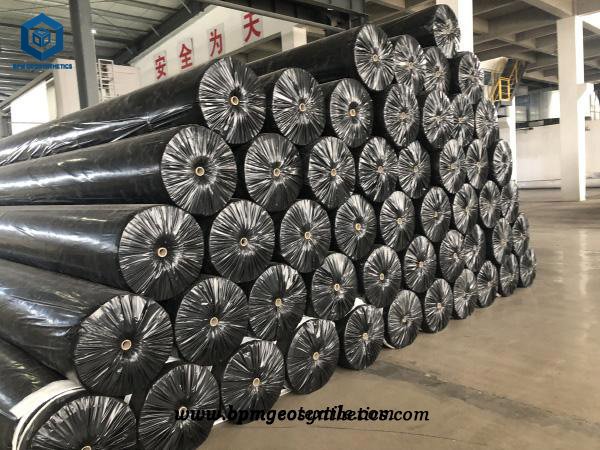

BPM customer from Nigeria contacted us through the company website and told us that he got a landfill project that required a large order of polypropylene geotextiles. Based on our previous experience in landfills, we recommend 250g, 300g woven polypropylene fabric and 1.5mm geomembrane for him. The Nigerian customer was a very strictly controlled engineering team. We mailed samples of polypropylene geotextile and geomembrane. They test the technical parameters of woven polypropylene fabric and geomembrane through their own equipment, and the quality of our products meets their technical requirements. After a month of communication, a Nigerian customer ordered a 250g polypropylene geotextile of 53,500 square meters and a 1.5mm geomembrane of 55,500 square meters. Through competitive prices, good product quality and professional after-sales service, we have won the trust of customers in BPM and become a long-term supplier.

Specifications of Woven polypropylene Fabric for Landfill Project in Nigeria

- Total polypropylene geotextile Quantity – 53,500 square meters

- polypropylene geotextiles specification –250gsm

- Each roll size is 7m*100m

- HDPE Landfill liner thickness – 1.5 mm

- Total Quantity – 55500 Square meters

- Roll Size – 7m*100m

About BPM

BPM has been specializing in delivering one stop geosynthetics products and solutions to worldwide customers since its foundation in 2007. BPM had provided many types of effective and state of the art geomembranes, geotextiles, geocells, geosynthetic clay liners (GCLs), drainage boards, geogrids to over 81 countries. Our main customers are from Australia, France, Sweden, UK, Hong Kong, Hungary, New Zealand, Poland, Mexico, Ecuador, Brazil, Pakistan, Bangladesh, Thailand, Vietnam, Malaysia, Indonesia, Singapore, Philippines, Sri Lanka, India, UAE, Saudi Arabia, Qatar, Kenya, Ghana, Ethiopia, Somalia, Nigeria, South Africa, Swaziland, Mongolia etc.

BPM is not only manufacturing best quality geosynthetic products but also providing professional design and installation service. OEM, ODM, custom development and fabrication are also available. If you have any questions or inquiries, please fill and submit the following form, we will reply as soon as possible.