The woven and non woven geotextile fabric are geotechnical materials used in civil engineering applications to improve the performance of soil and other materials. They can serve multiple functions such as filtration, drainage, separation, reinforcement, and erosion control. But there are frequently asked questions. Woven and non woven geotextile, what one is better? What is the Difference Between Woven and Non Woven Geotextile?How can we choose the right geotextile fabric for our specific projects?

BPM Geosynthetics is the leading geotextile manufacturer and supplier, we wholesale high quality geotextile fabric at competitive factory price. From the geotextile manufacturers’view, we will explore the key differences between woven and non woven geotextile fabric to help you select the right geotextile.

1 Introduction to Woven Geotextile and Non Woven Geotextile

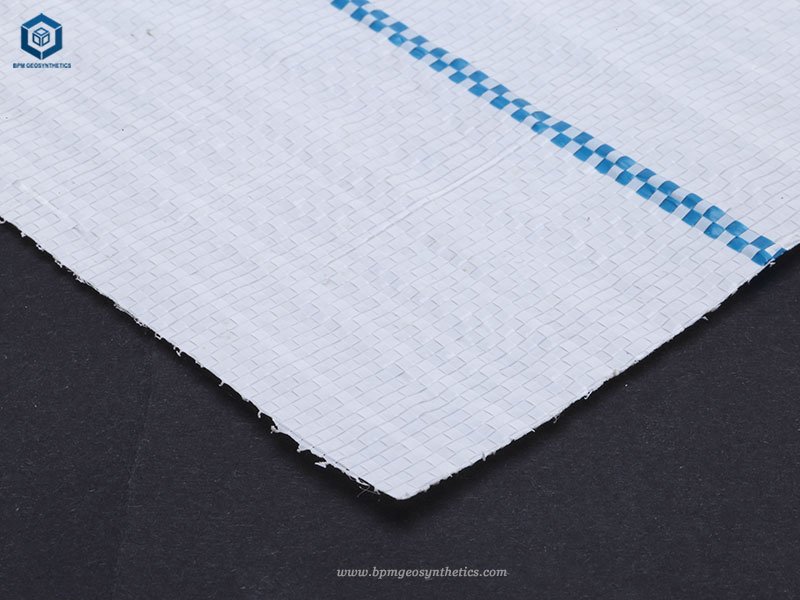

1.1 What is Woven Geotextile?

Woven geotextile is a geosynthetic material woven from high-strength synthetic fibers. Woven geotextile is manufactured by interlacing individual yarns or fibers, typically made of polypropylene or polyester, in a woven pattern. The weaving process creates a strong and durable fabric with distinct openings or pores. Compared with non woven geotextiles, woven geotextiles have a distinct fabric structure and fiber intersections.

1.2 What is Non Woven Geotextile?

Non woven geotextile is a geosynthetic material that has a different structure and manufacturing method compared to traditional woven geotextiles. Non woven geotextiles are made of synthetic fibers or natural fibers through fiber interweaving, fiber bonding or melting methods to form a non-woven structure.

2 Overview of Woven Geotextile

2.1 Construction and Manufacturing Methods

Woven geotextiles are made by interweaving synthetic fibers, such as polyester or polypropylene fibers. This woven structure allows the geotextile to have obvious vertical and horizontal intersections, forming a strong fabric.

2.2 Functions and applications

Woven geotextiles have a variety of functions and applications in the fields of civil engineering, environmental engineering and construction, including:

Separation. Woven geotextiles can isolate and separate different soil layers, preventing soil mixing and sediment migration.

Filtration. Woven geotextiles filter particulate matter from water flow, preventing soil erosion and erosion while allowing moisture to pass through.

Reinforcement. Woven geotextiles can enhance the strength and stability of the soil and reduce soil deformation and subsidence.

Protection. Woven geotextiles can be used to protect earthwork structures, river banks, dams and other earthworks from the erosion of water flow, waves and erosion.

2.3 Characteristics and performance

Woven geotextile has the characteristics of high strength, durability and weather resistance. They usually have high tensile strength and puncture resistance, and can withstand large mechanical stress and environmental pressure.

2.4 Installation and construction

The installation method of woven geotextile usually involves laying it on the surface or in the soil and taking appropriate fixing measures, such as nails, clamps or ground nails. In some cases, woven geotextiles may need to be stitched or welded to form a continuous layer covering a larger area.

3 Overview of Non Woven Geotextile

3.1 Structure and manufacturing method

The fibers of BPM non woven geotextiles are interwoven, bonded or fused through mechanical or chemical methods. This manufacturing method makes the geotextile have a disordered arrangement of fibers and no obvious fabric structure, but forms a continuous fiber network.

3.2 Functions and applications

Non woven geotextiles have functions similar to woven geotextiles, including separation, filtration, reinforcement and protection. They are widely used in the fields of civil engineering, environmental engineering and construction for:

- Separation. Non-woven geotextiles can isolate and separate different soil layers, preventing soil layers from mixing and sediment migration.

- Filtration. non woven geotextiles filter particulate matter from water flow, preventing soil erosion and erosion while allowing moisture to pass through.

- Reinforcement. Non-woven geotextiles can enhance the strength and stability of soil and reduce soil deformation and subsidence.

- Protection. non woven geotextiles can be used to protect earthwork structures, river banks, dams and other earthworks against the erosion of water flow, waves and erosion.

3.3 Characteristics and performance

Non woven geotextiles have a variety of characteristics and performances, such as tensile strength, water permeability, chemical resistance and weather resistance. Depending on the specific engineering needs, suitable non woven geotextile types and specifications can be selected.

3.4 Installation and construction

The installation method of non woven geotextiles is similar to that of woven geotextiles, which usually involves laying it on the surface or in the soil and taking appropriate fixing measures, such as nails, clamps or ground nails.

4 What is the Difference Between Woven and Non Woven Geotextile

Non woven and woven geotextiles are two types of geotechnical materials used in various civil engineering and construction applications. Although the two have similar uses, they have significant differences in manufacturing processes, structures, performance, and applications. On e of the main function of non woven Geotextile is to protect the Geomembrane, and the main function of woven Geotextile is to reinforce the foundation, etc. Here is the main differences:

4.1 Functions of Woven Geotextile

Woven geotextile is a material woven from polyester, polypropylene or other synthetic fibers that has high tensile strength and stiffness. It is commonly used in civil engineering and land management to reinforce and enhance the functionality of soil masses. The following are the reinforcement functions of Woven Geotextile:

4.1.1 Tensile strength

Woven Geotextile has high tensile strength and can resist the tensile force of the soil. When stress is applied to the soil, Woven Geotextile can disperse the tensile force over a larger area through its woven structure, thereby reducing the deformation and damage of the soil.

4.1.2 Spreading Loads

Due to the rigidity and strength of woven geotextile, it can be used to spread and transfer loads. In projects such as roads, railways and dams, Woven geotextile can be used as a reinforcing material to evenly distribute the load to a larger area and reduce the settlement and deformation of the soil.

4.1.3 Provide soil stability

Woven geotextile can be combined with the soil to increase the shear strength and anti-sliding stability of the soil. It can prevent the movement and dislocation of particles within the soil and improve the overall stability of the soil.

4.1.4 Control Soil Erosion

Woven geotextile can be used to control soil erosion. In places such as riverbanks, riverbeds and beaches, Woven geotextile can act as a protective layer to prevent soil erosion by currents and waves. It stabilizes the soil surface and slows water flow, preventing soil erosion and erosion.

Overall, woven geotextile is able to provide soil reinforcement and reinforcement through its high strength and rigidity, as well as its bonding with the soil. It is widely used in civil engineering to enhance soil stability, distribute loads and control soil erosion.

4.2 Functions of Non woven Geotextile

Non woven Geotextile plays an important role in protecting geomembrane. Geomembrane is an impermeable membrane used to prevent liquids or gases from penetrating into soil or other structures. Non woven geotextile can be used to protect geomembranes in the following ways:

4.2.1 Prevent Damage

Non woven geotextile can be used as a protective layer over the geomembrane to prevent external physical damage, such as sharp rocks or scratches from construction equipment. It provides a cushioning layer that absorbs external impacts, reducing stress on the geomembrane and the risk of damage.

4.2.2 Distributed loads

In some projects, such as the construction of roads or sidewalks, non-uniform foundation pressure may cause geomembrane to deform or be damaged. non woven geotextile can be used as a load-spreading layer, which evenly distributes loads and reduces concentrated stress on the geomembrane.

4.2.3 Prevent penetration

non woven Geotextile has a certain degree of water permeability and can be used to prevent groundwater or other liquids from penetrating underneath the geomembrane. It acts as a filter layer, blocking particulate matter from entering the geomembrane, while allowing moisture to flow through and maintain water balance.

4.2.4 Provide stability

Non woven geotextile can provide stability by increasing the friction between the geomembrane and the surrounding soil. It can bond with the soil to form a stable interface, preventing the Geomembrane from slipping or shifting.

In general, non woven geotextile plays an important role in protecting Geomembrane, providing physical protection, load distribution, anti-seepage and stability functions to ensure the normal operation and service life of geomembrane.

4.3 Comparation of Woven and Non Woven Geotextile Specifications

| 1 | Feature | Woven Geotextile | Non woven Geotextile |

| 2 | Structure | Woven structure | Non woven structure |

| 3 | Material | High strength fiber | Fiber or fiber mat |

| 4 | Stiffness | High Stiffness | Soft |

| 5 | Filtration performance | Generally | Good |

| 6 | Drainage performance | Generally | Good |

| 7 | Anti-permeability | Generally | Good |

| 8 | Application | Where high strength and durability are required, such as land stabilization, river embankment protection, road reinforcement, etc. | Soil filtration, soil conservation, land drainage and other occasions. |

5 How to Choose between Woven and Non Woven Geotextile for You Specific Project

The choice to use woven geotextile or non woven geotextile should be based on specific project needs and environmental conditions. Here are some considerations for selecting the right geotextile types:

5.1 Designed Functions

First determine the main functions required in the project, such as separation, filtering, enhancement or protection. Non woven geotextiles perform well in most functions, while woven geotextiles may be superior in terms of reinforcement and tensile strength.

5.1.1 Separation

If the project requires separation and isolation between different soil layers, both geotextile types can be used. non woven geotextiles can effectively prevent soil mixing and sediment migration.

5.1.2 Filtration

If you need to filter particulate matter from water flow and keep moisture from passing through, non woven geotextiles are a good choice. It has good water permeability and filtration properties.

5.1.3 Reinforcement

For projects requiring soil reinforcement, woven geotextiles are often more suitable. It has high tensile strength and stiffness and can withstand large mechanical stress.

5.1.4 Protection

Whether protecting earthwork structures, river banks, embankments or other earthworks, both woven and non woven geotextile types can be used. Choose the right geotextile types based on specific protection needs and environmental conditions.

5.2 Engineering environment

Consider the environmental conditions and soil characteristics of the project. The following factors may influence geotextile selection:

5.2.1 Soil Type

Understand the soil types in the project, including silt, clay, sand, rock, etc., and evaluate the adaptability of geotextiles in different soils.

5.2.2 Temperature and Humidity

Consider the climatic conditions and ambient temperature of the project. In high temperature or humid environments, non woven geotextiles may be more suitable.

5.2.3 Hydrological Conditions

Assess hydrological conditions, such as water flow velocity, water level changes, and water quality, to determine the water permeability and filtration performance requirements of the geotextile.

5.2.4 Design requirements

Select the appropriate geotextile type and specification according to the design requirements and specifications of the project. Consult relevant engineering guidelines and specifications to ensure the geotextile selected meets requirements.

5.3 Cost Effectiveness

Consider the budget and economic benefits of the project. non woven geotextiles are generally more affordable than woven geotextiles, but in certain applications the high strength and durability of woven geotextiles may provide longer-term benefits.

The best choice should be based on a combination of the above factors and discussion with a geotechnical professional. They can provide more specific advice and recommendations based on specific project requirements and experience.

6 Summary

When geotextiles need to be used in construction, the construction party can choose to use Woven Geotextile or non woven Geotextile based on the design requirements, applications and characteristics of the project. The non woven geotextile is ideal to protect geomembrane, while the woven geotextile is the best geosynthetic material for soil reinforcement.

BPM Geosynthetics manufactures and supplies high quality woven and non woven geotextile fabric with great price. If you have any problems when making choice between woven and non woven geotextile. Please contact us as soon as possible.

Thank you for reading.