A landfill liner, also known as composite liner, is a low permeable barrier placed beneath engineered landfill sites. Its purpose is to prevent leachate, along with its harmful constituents, from infiltrating nearby aquifers or rivers, thereby averting water pollution. BPM Geomembrane offers landfill liner with custom size and thickness at best factory price.

BPM Geosynthetics specializes in providing high-quality composite geomembrane liner with custom size and thickness in bulk order at competitive factory prices. Our products can be customized in terms of size and thickness to meet the specific requirements of each project.

1. What Is A Landfill Liner?

A landfill liner is a layer or system of layers designed to prevent contaminants from leaching into the surrounding environment from a landfill. The primary purpose of a composite liner is to protect groundwater and nearby surface water from pollution by preventing the migration of hazardous substances present in the waste deposited in the landfill. landfill liner is intended to be a low permeable barrier, which is laid down under engineered landfill sites. Until it deteriorates, the liner retards migration of leachate, and its toxic constituents, into underlying aquifers or nearby rivers, causing potentially irreversible contamination of the local waterway and its sediments.

Typically, a landfill liner system consists of several components, which may include:

1.1 Bottom Liner

This is the primary barrier between the waste and the underlying soil and groundwater. It is usually made of impermeable materials such as geomembranes (synthetic liners) or compacted clay.

1.2 Leachate Collection System

Beneath the liner, there is often a network of pipes and collection channels designed to capture leachate, which is the liquid that forms as water percolates through the waste. Leachate can contain hazardous substances, so it needs to be properly managed and treated.

1.3 Drainage Layer

Some landfill liners include a layer of gravel or sand above the liner to enhance drainage and facilitate the movement of leachate to the collection system.

1.4 Protective Cover

On top of the waste and liner system, there may be a layer of soil or other materials to provide additional protection, manage odors, and control erosion.

Modern landfills generally require a layer of compacted clay with a minimum required thickness and a maximum allowable hydraulic conductivity, overlaid by a high-density polyethylene geomembrane.

2. What Is The Composition of Landfill Liner?

2.1 Geomembrane Layer

Geomembrane layer is a synthetic membranes used as impermeable barriers in geotechnical and environmental projects. Geomembrane layer can be HDPE geoemmbrane, LLDPE geomembrane, or PVC geomembrane provides essential functions such as containment, fluid control, and environmental protection. With their impermeability, durability, flexibility, and weldability, geomembranes have become indispensable in a wide range of applications across various industries.

2.2 Protection Layer

The protection layer is a permeable synthetic textile material used in geotechnical and civil engineering applications. It is made from synthetic fibers, such as polypropylene or polyester, and is designed to provide filtration, separation, reinforcement, and erosion control functions in various construction projects.

3. What Is The Purpose of Landfill Liner?

The purpose of a landfill liner is important in ensuring the proper containment of waste and preventing environmental pollution.

3.1 Preventing waste leakage

The geomembrane, which serves as the core component of the anti-seepage layer, plays a vital role in preventing waste materials from leaking into the soil and groundwater. By acting as a barrier, the liner inhibits the migration of contaminants, such as hazardous chemicals and pollutants, from the landfill into the surrounding environment. This helps safeguard the quality and integrity of the soil and groundwater resources.

3.2 Preventing environmental pollution

The presence of an effective anti-seepage layer, including the composite liner, significantly reduces or eliminates the risk of waste pollution to the soil, groundwater, and the surrounding ecosystem. By containing the waste within the landfill boundaries, the liner prevents leachate formation, which is a toxic liquid generated when water interacts with waste materials. Leachate contains harmful substances that can contaminate soil, water sources, and nearby ecosystems. The landfill liner acts as a protective barrier, minimizing the potential for environmental pollution and protecting the overall ecological balance.

3.3 Improving the stability of the landfill

The anti-seepage layer, including the landfill liner, plays a crucial role in enhancing the structural stability of the landfill. It helps distribute the weight and stress of the waste evenly, reducing the risk of foundation settlement. Additionally, the liner helps prevent soil erosion, as it acts as a barrier against the movement of waste materials and water. By minimizing erosion, the liner preserves the integrity of the landfill structure and prevents the release of waste into adjacent areas.

4. How To Install Landfill Liner?

Landfill liner construction and installation specifications are as follows:

4.1 Preparation work before laying

Develop a construction plan according to the construction organization design;

Select composite liner materials according to design requirements;

Foundation treatment: Remove all sharp and hard objects on the ground that may damage the landfill liner, fill in potholes, level the soil surface or repair the slope surface.

Laying environment: The outdoor temperature is above 5℃, the wind force is below level 4, and there is no rain or snow.

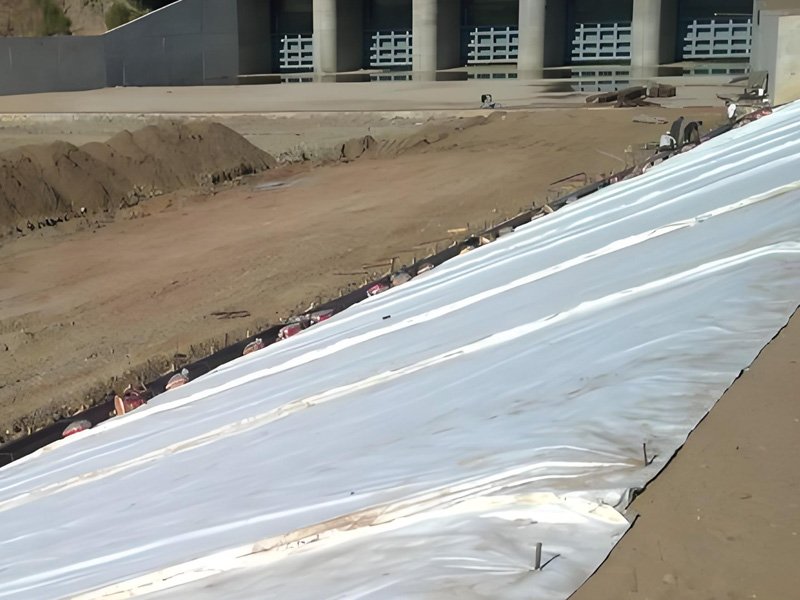

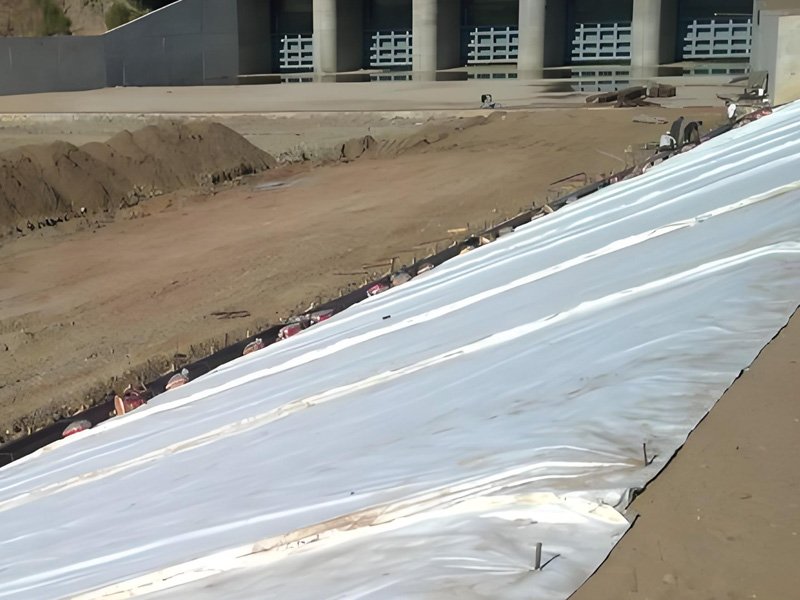

4.2 Landfill liner laying method

Large bundles of landfill liner should be laid using tractors, winches and other machinery. If the conditions are not met and small bundles of composite liner are available, manual laying can also be used. For slope laying, a winch is used to slowly spread it from the top of the slope to the bottom of the slope, and the top and bottom of the slope are buried in fixed ditches.

Lay landfill liner in zones and blocks according to the specified order and direction.

When laying composite liner, it should be appropriately relaxed and avoid manual bending and damage.

When laying composite liner, the joints formed between modules should be T-shaped and not cross-shaped.

There should be no dirt, sand, water (including dew) and other debris that affects the welding quality on the overlapping surface of the landfill liner weld.

When laying liner on a slope, its joint arrangement direction should be parallel or perpendicular to the maximum slope line, and it should be laid in a bottom-up order.

At the bends of the slope, the liner and joints should be properly attached to the slope.

After the composite liner is laid, before it is covered with a protective layer, a 20-40Kg sandbag should be placed at the corners of the landfill liner every 2-5m.

landfill liner should be naturally relaxed and firmly attached to the supporting surface, and should not be pleated or suspended.

4.3 On-site connection of landfill liner

Ensuring the integrity of the joints is the prerequisite for ensuring effective isolation and long-term work of the landfill liner.

The connection work of liner should not be carried out under adverse weather conditions to ensure the quality of the connection.

In the case of heat sealing, overheating should be avoided to prevent blistering at the joint.

Adhesion between composite liner made of different raw materials should be avoided as much as possible, and special research should be conducted when unavoidable.

Landfill liner welding method: hot wedge welding method, its advantages:

- There is no need to roughen the surface of the membrane.

- During the welding process, there is no need to add new substances to form the weld.

- Its heat source control is separated from the HDPE geomembrane. The welding form should be double weld overlap, with a line width of 12mm and a clear distance of 10mm between the two lines.

Use clean gauze to wipe the overlap of the weld to ensure that it is free of water, dust and dirt. The landfill liner should be aligned in parallel and overlap appropriately.

Welding quality control: Adjust the welding equipment to the best working condition according to the local climate conditions and material properties at that time. During the welding process, attention should be paid to the selection of temperature, speed and pressure.

Carry out a small sample welding test first, and try to weld a 1m-long HDPE liner sample. Use an on-site tearing inspection test. If the weld is not damaged by tearing and the base material is torn, it is considered qualified.

After passing the on-site tear test, formal welding will be carried out one by one.

5. Conclusion

The landfill liner plays a crucial role in both environmental protection and waste management. It serves as a crucial barrier layer that prevents the leakage of waste materials into the surrounding environment, safeguarding ecosystems and water sources from contamination. It also contributes to the overall stability of the landfill, reducing the risks of settlement and soil erosion.

Advancements in materials, such as geomembranes, can lead to improved impermeability and durability, ensuring more effective containment of waste.

Future research and innovation efforts hold the potential to improve the performance, durability, and sustainability of barrier layers in landfills, ultimately contributing to more effective waste management practices and enhanced environmental protection.