A 30 mil HDPE liner refers to a high-density polyethylene liner with a thickness of 30 mil, which is equivalent to 0.030 inches or 0.76 millimeters. HDPE liners are commonly used in various applications such as landfill liners, pond liners, and containment systems for liquids or hazardous materials. The 30 mil thickness provides a durable and impermeable barrier, offering excellent resistance to chemicals, punctures, and UV degradation. These liners are typically installed to prevent leakage and protect the surrounding environment and infrastructure.

BPM GEOSYNTHETICS products can be customized in size and thickness to meet the specific requirements of each project.In this article, let’s explore its knowledge together.

1.What Is 30 mil HDPE Liner?

30 mil HDPE liner is a type of high-density polyethylene (HDPE) liner that is commonly used in various civil engineering projects, such as landfills, ponds, and wastewater treatment facilities.

HDPE liners are known for their excellent chemical resistance, puncture resistance, and durability, making them ideal for applications where containment and protection against environmental contamination are critical. A 30 mil HDPE liner offers a good balance between strength and flexibility, allowing it to conform to the contours of the underlying soil while providing a reliable barrier against the migration of liquids and gases.

2. What Are Functions Of 30 Mil HDPE Liner?

A 30 mil HDPE Geomembrane serves several important functions in various applications. Here are the primary functions of a 30 mil HDPE liner:

2.1 Contaminant Containment

A 30 mil HDPE Sheet is designed to contain hazardous waste and prevent contaminants from leaking into the soil and groundwater. This is particularly crucial in landfill and waste management sites.

2.2 Fluid Impoundment

Liners are used to create ponds, reservoirs, and other water storage or collection systems, ensuring that water is retained and impounded effectively.

2.3 Foundation Protection

In construction projects, a 30 mil Geomembrane liner can protect foundations from water intrusion, thereby preventing structural damage.

2.4 Chemical Resistance

The material is resistant to many chemicals, making it suitable for use in industrial settings where chemical exposure is possible.

2.5 Puncture Resistance

The 30 mil thickness provides added resistance to physical damage from sharp objects or heavy equipment traffic.

2.6 Ultraviolet (UV) Resistance

While not all HDPE liners are inherently UV resistant, they can be protected from UV degradation through the use of cover materials or specific formulations.

3. What Are Applications Of 30 mil HDPE Liner?

30 mil HDPE liner is commonly used in various applications that require containment and barrier properties. Some of its applications include:

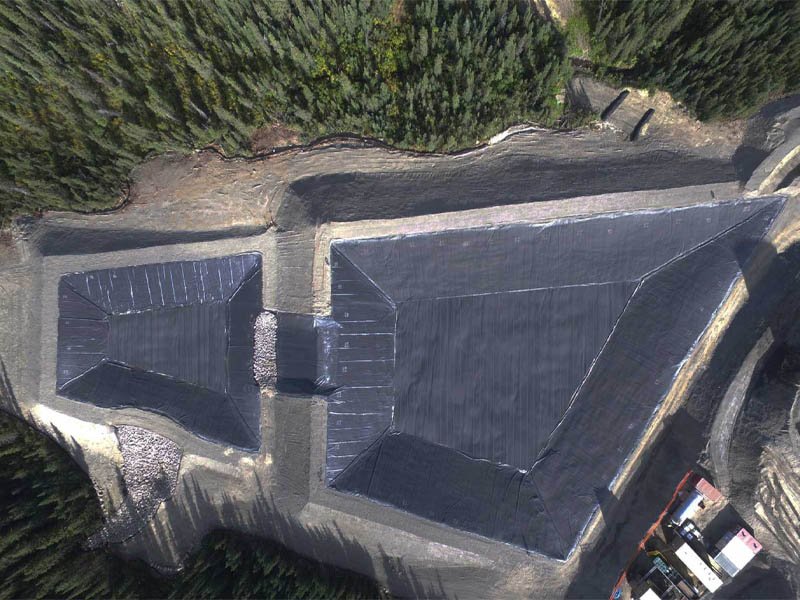

3.1 Landfill Liners

30 mil HDPE liner is widely used as a primary barrier system in landfill engineering to prevent the migration of contaminants from waste materials into the surrounding environment.

3.2 Pond and Reservoir Barriers

It is used to line ponds, reservoirs, and other water containment structures to prevent seepage and leakage, ensuring water conservation and protection.

3.3 Cap Liner for Abandoned Dumps

Seal off and remediate old waste sites.

3.4 Wastewater Treatment Systems

HDPE liners are employed in water and wastewater treatment facilities to line basins, clarifiers, and other containment structures, preventing leakage and ensuring proper containment of treated water or sludge.

3.5 Leakage Protection for Water Parks

Prevent water loss in recreational facilities.

3.6 Erosion Control

Stabilize slopes and embankments, reducing soil erosion.

3.7 Chemical Storage Areas

Safeguard against chemical spills and seepage.

3.8 Leachate Collection Systems

Capture and manage landfill leachate.

3.9 Gas Collection Systems

Prevent gas migration in landfill sites.

3.10 Underground Drip Irrigation

Provide moisture barriers for agriculture.

4. How To Install 30 mil HDPE Liner?

Installing a 30 mil HDPE (high-density polyethylene) liner involves several steps to ensure it functions properly as a barrier. Here’s a brief guide:

4.1 Site Preparation

- Clear the site of rocks, debris, and sharp objects.

- Grade the soil to a smooth surface, removing bumps or depressions.

4.2 Inspection

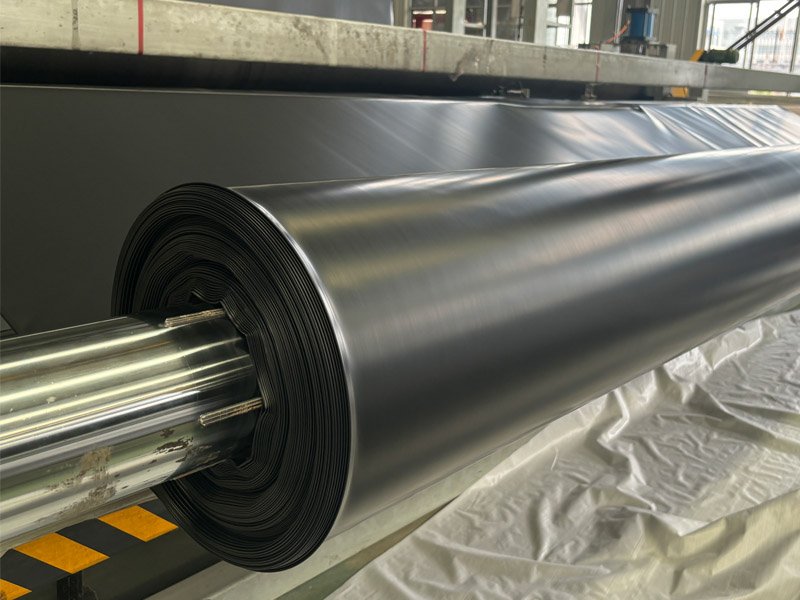

- Inspect the liner roll for any damage before deployment.

4.3 Unrolling and Positioning

- Unroll the HDPE liner on the prepared surface.

- Ensure there’s enough excess material for overlapping and seaming.

4.4 Seaming

- If multiple sheets are used, they must be seamed together using hot air, wedge, or strip heating methods.

4.5 Anchoring

- Anchor the liner to the ground using soil, stakes, or anchor trenches to prevent movement.

4.6 Leak Testing

- Conduct a leak test to ensure the liner is free from holes or tears.

4.7 Protection

- Cover the liner with a protective layer of soil, fabric, or other materials to shield it from mechanical damage during subsequent construction activities.

4.8 Monitoring

- Regularly inspect the liner for any signs of damage and address immediately if found.

5. Summary

30 Mil HDPE liner is a thick, high-density polyethylene material used in various applications for contaminant containment, fluid impoundment, and erosion control. It is commonly installed in landfills, ponds, reservoirs, and wastewater treatment systems to create an impermeable barrier, protecting the environment from pollutants and maintaining water storage.

Any questions, please contact us.