In recent years, the adoption of Low-Density Polyethylene (LLDPE) geomembrane has gained traction in various engineering and environmental applications. LLDPE geomembrane offer advantages such as flexibility, chemical resistance, and ease of installation.BPM Geosynthetics specializes in providing high-quality geomembrane liner with custom size and thickness in bulk order at competitive factory prices.

However, like any material, LLDPE geomembrane also come with their own set of disadvantages that warrant consideration.

1. What Are LLDPE Geomembrane?

LLDPE geomembrane, or Low-Density Polyethylene geomembranes, is a type of synthetic liner used primarily in geotechnical and environmental engineering applications. It is made from low-density polyethylene, a thermoplastic polymer known for its flexibility, toughness, and chemical resistance. LLDPE geomembrane are manufactured through a process of extrusion, which produces continuous sheets of material with uniform thickness and properties.

It is commonly used in fields such as environmental engineering, water conservancy engineering and civil engineering. It has excellent stretch resistance, tear resistance, chemical resistance and aging resistance, as well as good flexibility and plasticity. LLDPE geomembrane is a high-quality geomembrane produced with a special formula, using special linear low-density polyethylene (LLDPE) resin, and using advanced production technology. It has extremely high unidirectional and multi-directional elongation performance and softness. . It is very suitable for projects with uneven settlement or large local settlement, such as mining heap leach fields, landfill closures and other projects that require high material elongation properties and puncture resistance.

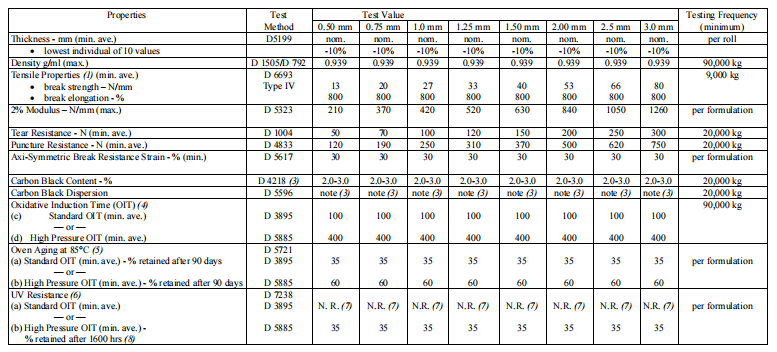

Product specifications: width 1000-7000mm, thickness 0.5-3.0mm.

Implementation standard: GRI-GM17

2. What Are Advantages Of LLDPE Geomembrane?

2.1 Flexibility and Adaptability

LLDPE geomembrane has high flexibility and can adapt to various terrain and geological conditions. Its material properties enable it to adapt to deformation and movement in complex surface and underground structures, ensuring effective anti-seepage effects.

2.2 Chemical Stability

LLDPE geomembrane has good chemical stability and can resist the erosion of many common chemicals, such as acids, alkalis, salts and organic solvents. This gives it excellent durability in environments containing corrosive substances.

2.3 Aging Resistance

By adding specific antioxidants and UV stabilizers, LLDPE geomembrane can resist UV radiation and oxidative damage, extending its service life. This makes it ideal for long-term outdoor exposure.

2.4 Low Permeability

LLDPE geomembrane has excellent anti-seepage properties, which can effectively prevent the penetration and leakage of water, chemicals and pollutants, and protect the quality of groundwater sources and soil.

2.5 Ease of Construction

LLDPE geomembrane is relatively lightweight, easy to cut and carry, and the construction process is simple and efficient. It can be installed by hot melting, welding or bolting, and is suitable for various terrains and environmental conditions.

2.6 Environmental Friendliness

As a plastic material, LLDPE geomembrane can reduce environmental impact through recycling or safe disposal. Its long-term durability and chemical stability also help reduce resource consumption and pollution.

3. What Are Disadvantages Of LLDPE Geomembrane?

3.1 Permeability

One of the significant disadvantages of LLDPE geomembranes is their relatively higher permeability compared to other geomembrane materials like HDPE (High-Density Polyethylene). This higher permeability can lead to potential issues in containment applications where strict control over fluid or gas migration is required.

3.2 Temperature Sensitivity

LLDPE geomembranes may exhibit sensitivity to temperature variations. Extreme temperatures can affect their physical properties and performance, potentially compromising their effectiveness in certain environments.

3.3 UV Degradation

Like many polyethylene materials, LLDPE geomembranes are susceptible to degradation from exposure to ultraviolet (UV) radiation. Without adequate UV stabilization, these geomembranes may experience premature aging, embrittlement, and reduced service life when used in outdoor applications.

3.4 Mechanical Properties

While LLDPE geomembranes offer flexibility, they may have lower tensile strength and puncture resistance compared to thicker or more rigid geomembrane materials. This can increase the risk of damage during installation or over time, especially in high-stress environments.

3.5 Chemical Compatibility

While LLDPE geomembranes generally exhibit good chemical resistance, they may not be suitable for containing certain aggressive chemicals or substances. Compatibility testing is essential to ensure the geomembrane’s performance and longevity in specific chemical environments.

3.6 Long-Term Durability

Despite their initial cost-effectiveness, LLDPE geomembranes may have a shorter lifespan compared to materials like HDPE or PVC (Polyvinyl Chloride) geomembranes. Factors such as UV exposure, chemical exposure, and mechanical stress can contribute to degradation over time, necessitating costly repairs or replacements.

3.7 Seaming and Installation Challenges

LLDPE geomembranes may present challenges during seaming and installation due to their flexibility and relatively low melting point. Proper installation techniques and quality control measures are crucial to ensure seam integrity and overall performance, which can add complexity and cost to projects.

3.8 Environmental Concerns

There are also environmental concerns associated with the production and disposal of LLDPE geomembranes. The manufacturing process may involve the use of fossil fuels and other non-renewable resources, while disposal at the end of the geomembrane’s life cycle can contribute to plastic waste and environmental pollution.

4. How To Choose Different Thicknesses Of LLDPE Geomembrane In Different Applications?

The different thicknesses of LLDPE geomembrane in engineering applications can be selected according to specific project requirements and scene needs. Geomembranes of different thicknesses are suitable for different engineering applications. The following are typical applications of different thicknesses of LLDPE geomembrane.

Tech Data as Below

Thickness Below 0.5mm

Usually used in light environmental engineering applications, such as anti-seepage layers in small ponds, artificial lakes, flower beds, etc. It is suitable for some simple civil engineering projects, such as simple foundation isolation, underground storage tank seepage prevention, etc.

5mm – 1.0mm Thickness

Commonly used in medium-scale environmental engineering projects, such as landfills, sewage treatment tanks, chemical pollution prevention and control projects, etc. It is also suitable for some civil engineering projects, such as tunnels, anti-seepage layers of underground pipelines, waterproof layers of underground buildings, etc.

Thickness Above 1.0mm

It is suitable for engineering projects that require higher anti-seepage performance, such as large-scale water conservancy projects, heavy-duty environmental projects, etc. Usually used as the main anti-seepage layer in water conservancy projects such as underground reservoirs, levees, and dams.

It should be noted that the thickness selection of LLDPE geomembrane should be determined according to the specific requirements of the project, taking into account factors such as the engineering environment, geological conditions, surface load, expected service life, and budget. When selecting geomembrane thickness, engineering design and technical evaluation are recommended to ensure the appropriate thickness is selected to meet the long-term needs of the engineering project.

5. Summary

To sum up, LLDPE geomembrane has a series of advantages, but it also has some disadvantages and limitations. In actual engineering applications, its advantages and disadvantages need to be fully considered, and appropriate geomembrane materials and thicknesses should be selected according to specific project needs and scene characteristics to ensure the long-term stability and reliability of the engineering project. At the same time, through continuous technological innovation and research and development, the performance and applicability of geomembranes can be further improved, and their widespread application in environmental protection and engineering construction can be promoted.

Any questions, please contact us.