- High Strength and Durability

- Effective Filtration

- Corrosion Resistance

- Chemical And UV Resistance

- High Extension and Temperature Resistance

- Easy Handling and Installation

- ODM/OEM Availability

- Great Factory Price

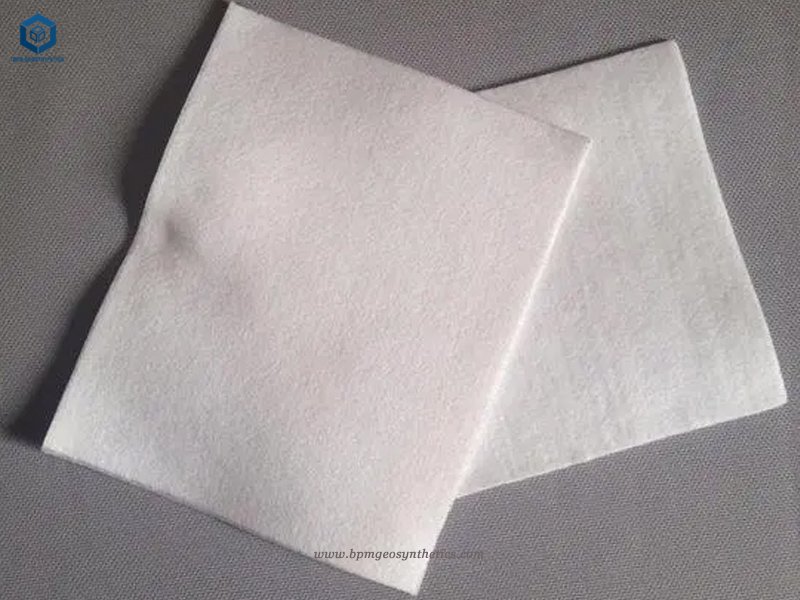

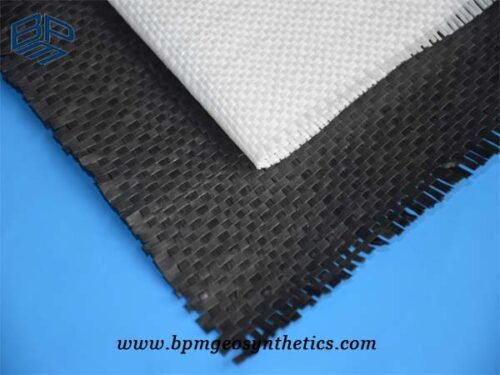

Short Staple Non Woven Needle Punched Geotextile Fabric

Description

Non woven needle punched geotextile is a high-strength fabric produced by needle punching staple fibers in a random pattern. This manufacturing process ensures dimensional stability and durability. Made from polypropylene fibers, the geotextile resists deterioration caused by UV light exposure and remains unaffected by commonly found soil chemicals. With its commercial grade quality, BPM Non woven needle punched geotextile offers versatile applications in filtration, stabilization, separation, and drainage. It effectively filters soil particles while providing stabilization for various construction projects. The geotextile also acts as a separator, preventing the mixing of different soil layers or materials.

1. What Is Non Woven Needle Punched Geotextile Fabric?

Non woven needle punched geotextile fabric is a type of geosynthetic material widely utilized in civil engineering and construction projects. It plays a crucial role in increasing soil stability, providing erosion control, and aiding in drainage. BPM Geosynthetics offers a reliable and high-quality solution with their Non Woven Needle Punched Geotextile fabric, which is manufactured using synthetic polymers such as polypropylene, polyester, polyethylene, or polyamides fibers.

The fabrication process involves several methods, including weaving, needle punching, or heat bonding, to create a robust and durable non-woven geotextile fabric. However, the needle punching technique is particularly popular. In this process, barbed needles are repeatedly punched through layers of synthetic fibers, intertwining and interlocking them to form a strong and dimensionally stable fabric.

BPM non woven needle punched geotextile fabric is its exceptional impermeability and resistance to deformation. The fabric effectively stabilizes the soil and provides ground support, enhancing the integrity of the construction site. It allows water to permeate through its structure while retaining soil particles, making it an effective solution for managing drainage and preventing erosion.

BPM’s geotextile fabric finds extensive applications in civil engineering, including roads, harbors, reservoirs, canals, dams, and various retaining structures. By utilizing the non-woven needle punched geotextile fabric, soil stabilization can be significantly improved, erosion can be controlled, and drainage can be efficiently managed. The fabric’s high strength, dimensional stability, and resistance to UV deterioration and soil chemicals make it an ideal choice for demanding environments and long-lasting infrastructure projects.

With their commitment to quality and innovation, BPM Geosynthetics provides a reliable and versatile solution for civil engineering, infrastructure, and environmental projects. Their Non Woven Needle Punched Geotextile fabric offers durability and performance, ensuring soil stability, erosion control, and efficient drainage in a wide range of applications.

2. Specifications of Short Staple Needled Punched Geotextile Fabric

| Item | Unit | BPM10 | BPM15 | BPM20 | BPM25 | BPM30 | BPM35 | BPM40 | BPM45 | BPM50 | BPM60 | BPM80 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Mechanical Properties (MD=Machine Direction Strength/CD=Cross Machine Direction Strength) | ||||||||||||

| Weight | g/m2 | 100 | 150 | 200 | 250 | 300 | 350 | 400 | 450 | 500 | 600 | 800 |

| Weight Variation | % | -8 | -8 | -8 | -8 | -7 | -7 | -7 | -7 | -6 | -6 | -6 |

| Thickness | mm | 0.9 | 1.3 | 1.7 | 2.1 | 2.4 | 2.7 | 3 | 3.3 | 3.6 | 4.1 | 5 |

| Width Variation | % | -0.5 | ||||||||||

| Break Strength (MD and XMD) | kN/m | 2.5 | 4.5 | 6.5 | 8 | 9.5 | 11 | 12.5 | 14 | 16 | 19 | 25 |

| Break Elongation | % | 25-200 | ||||||||||

| CBR Burst Strength≥ | kN | 0.3 | 0.6 | 0.9 | 1.2 | 1.5 | 1.8 | 2.1 | 2.4 | 2.7 | 3.2 | 4 |

| Hydraulic Properties | ||||||||||||

| Sieve Size O90 | mm | 0.07-0.02 | ||||||||||

| Permeability Coefficient | cm/s | (1.0-9.9)× (10-1 ~ 10-3) | ||||||||||

3. What Are Advantages of Non Woven Needle Punched Geotextile Fabric?

Non-woven needle-punched geotextile fabric offers several advantages that make it a preferred choice in civil engineering and construction projects. Here are the key advantages of this fabric:

3.1 High Strength and Durability

The mechanical interlocking of synthetic fibers during the needle-punching process results in a fabric with excellent tensile strength and durability. It can withstand heavy loads and environmental stresses, providing long-lasting performance.

3.2 Effective Filtration

The fabric allows water to pass through while retaining soil particles, providing effective filtration. This helps prevent soil erosion, maintain soil stability, and improve drainage efficiency in various applications. Geotextile fabrics can also be designed with controlled permeability, allowing them to regulate the flow of water. They can facilitate rapid water flow in drainage applications or control water seepage in containment structures.

3.3 Corrosion Resistance

Non-woven needle-punched geotextile fabric exhibits resistance to common chemical substances found in soil, gasoline, diesel, and other corrosive agents. This resistance ensures its longevity and performance in challenging environments.

3.4 Chemical Resistance

These fabrics can be engineered to resist chemical degradation caused by exposure to aggressive substances like acids and alkalis. This property ensures their stability and performance over time.

3.5 UV Resistance

Many needle-punched geotextiles are treated with UV stabilizers, making them resistant to the damaging effects of ultraviolet (UV) radiation. This enhances their longevity and performance when exposed to sunlight.

3.6 High Extension and Temperature Resistance

The fabric exhibits good elongation under stress, allowing it to adapt to uneven surfaces. It also offers high-temperature resistance, making it suitable for applications such as asphalt laying.

3.7 Easy Handling and Installation

Non-woven needle-punched geotextile fabric is lightweight and easy to handle, transport, and install. Its flexibility allows for easy cutting and shaping to fit various project requirements, reducing installation time and labor costs.

These advantages make non-woven needle-punched geotextile fabric an ideal choice for various civil engineering applications, providing reliable performance, durability, and cost-effectiveness.

4. What Is Non Woven Needle Punched Geotextile Fabric Used For?

Non woven needle punched geotextile fabric finds various applications in civil engineering and construction projects. Some common uses include:

4.1 Cushioning and reinforcement

The fabric provides cushioning and reinforcement against subgrade surface irregularities, helping to distribute concentrated forces and prevent puncture failure.

4.2 Retaining wall backfill reinforcement

It is used to reinforce the backfill in retaining walls, providing stability and preventing soil erosion.

4.3 Road stabilization and crack repair

Non-woven needle-punched geotextile fabric is employed to strengthen weak roads and fix cracks, enhancing the durability and performance of the road surface.

4.4 Slope stability and soil reinforcement

non woven needle punched geotextile improves the stability of slopes and reinforces soil, preventing erosion, water and soil loss, and soil freezing damage.

4.5 Isolation layer

The non woven geotextile fabric acts as an isolation layer between different soil layers or materials, such as artificial backfill soil stone and the foundation, or in areas with varying ground conditions.

4.6 Filtration layer

Non woven needle punched geotextile fabri serves as a filtration layer for drainage systems, such as drainage pipes or gravel, preventing soil particles from clogging the pipes while allowing water to pass through.

4.7 Vertical or horizontal drainage

The non woven needle punched geotextile fabric can be buried in the soil to facilitate vertical or horizontal drainage, releasing air pressure and preventing water accumulation.

4.8 Foundation reinforcement

Non woven needle punched geotextile fabri is used to reinforce weak foundations in various engineering projects, including roads, railways, embankments, and airports, improving their stability and load-bearing capacity. Non-woven needle-punched geotextile fabric offers versatility and reliability in these applications, providing enhanced performance, durability, and stability to the underlying structures.

5. About BPM

BPM had been specializing in delivering one stop geosynthetics products and solutions to worldwide customers since its foundation in 2007. BPM had provided many types of effective and state of the art geomembranes, geotextiles, geocells, geosynthetic clay liners (GCLs), drainage boards, geogrids to over 36 countries. Our main customers are from Australia, France, Sweden, UK, Hong Kong, Hungary, New Zealand, Poland, Mexico, Ecuador, Brazil, Pakistan, Bangladesh, Thailand, Vietnam, Malaysia, Indonesia, Singapore, Philippines, Sri Lanka, India, UAE, Saudi Arabia, Qatar, Kenya, Ghana, Ethiopia, Somalia, Nigeria, South Africa, Swaziland, Mongolia etc.

BPM is not only manufacturing best quality geosynthetics products but also providing professional design and installation service. OEM, ODM, custom development and fabrication are also available. If you have any questions or inquiries, please fill and submit the following form, we will reply as soon as possible.