HPDE Geocell is the three dimensional cellular confinement product which features lower cost, easy deployment, high strength and permeability. BPM high quality HDPE geocell is made of high density polyethylene (HDPE) and jointly welded by ultrasonic technology to ensure consistency, resistance to erosive forces. BPM geocells widely used in construction for erosion control, soil stabilization on flat ground, shorelines, steep slopes, multi-layered retaining walls, channel protection and structural reinforcement for heavy duty load support roads and earth retention.

HDPE Geocell

Description

Geocell is the three dimensional cellular confinement product which features lower cost, easy deployment, high strength and permeability. BPM high quality HDPE geocell is made of high density polyethylene (HDPE) and jointly welded by ultrasonic technology to ensure consistency, resistance to erosive forces. The HDPE geocell feature of longer lasting performance, flexible package and a wide range of cell sizes and depths to meet your project and civil engineering application requirements. The unique, lightweight, flexible material conforms to surface variations to improve ease of installation while resisting impact damage. BPM geocells are widely used in construction for erosion control, soil stabilization on flat ground, shorelines, steep slopes, multi-layered retaining walls, channel protection and structural reinforcement for heavy duty load support roads and earth retention.

Geocell Products

HDPE Geocell Specifications

| Product Type | Height(mm) | Welding Distance(mm) | Thickness(mm) | Tensile Strength of Welding Points(N/cm) | Tensile Strength of Connection of Cells(N/cm) | Tensile Strength at Yield of Each Sheet(MPa) |

|---|---|---|---|---|---|---|

| Smooth and Not Perforated | 50≤H≤250 | 330≤A≤1000 | 1.0~1.4 | ≥100 | ≥120 | ≥20 |

| Smooth and Perforated | 50≤H≤250 | 330≤A≤1000 | 1.0~1.4 | ≥100 | ≥120 | ≥20 |

| Textured and Not Perforated | 50≤H≤250 | 330≤A≤1000 | 1.5~1.7 | ≥100 | ≥120 | ≥20 |

| Textured and Perforated | 50≤H≤250 | 330≤A≤1000 | 1.5~1.7 | ≥100 | ≥120 | ≥20 |

| Remarks: 1. This is a basic technical specification. 2. All of the technical indexes can be reached according to the customers’ demand, and the other special standards will be carried out by agreement or contact. | ||||||

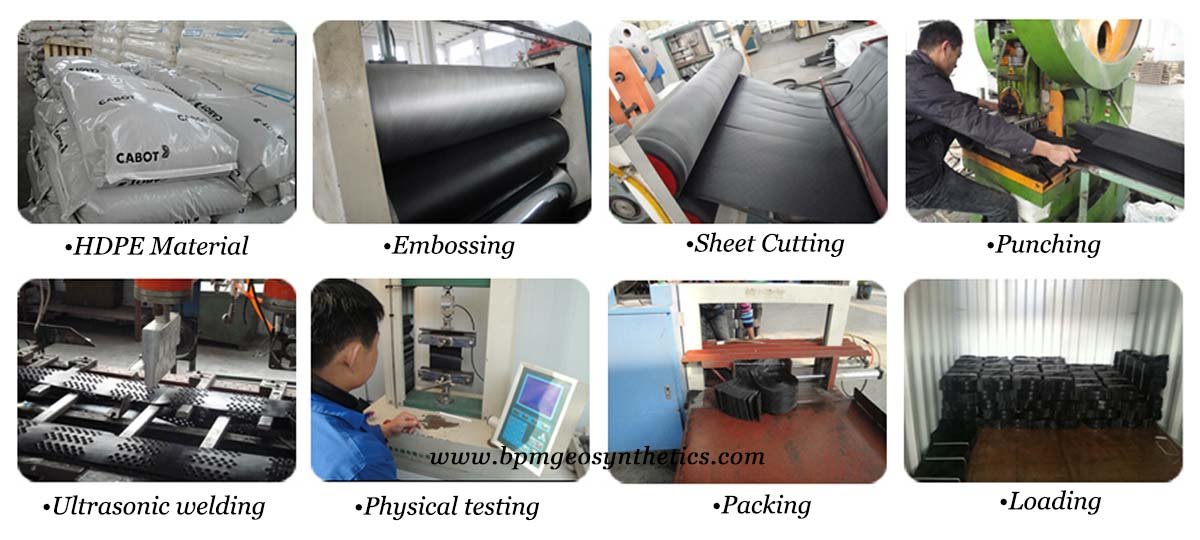

HDPE Geocell Production Process

Geocell Production Process

The main HDPE geocell production processes include virgin HDPE resin sourcing, geocell formation and embossing, geocell sheet cutting, honeycomb structure punching, ultrasonic welding, physical performance testing, pacaking and loading. All these processes are finished in BPM own factory.

HDPE Geocell Applications

- Load support: Solve unacceptable road, parking and yard surface problems.

- Slope protection: Create a stable environment for long-term sustainability of embankment material.

- Channel protection: Ensure stability and protection of channels exposed to all types of erosive conditions.

- Vegetated retaining walls: including steepened slopes, retaining walls, gravity walls and so on.

- Shorelines: Provide unique solutions to prevent erosion problems caused by water contact, surface flow and wave action.

Geocell Applications

About BPM

BPM had been specializing in delivering one stop geosynthetics products and solutions to worldwide customers since its foundation in 2007. BPM had provided many types of effective and state of the art geomembranes, geotextiles, geocells, geosynthetic clay liners (GCLs), drainage boards, geogrids to over 36 countries. Our main customers are from Australia, France, Sweden, UK, Hong Kong, Hungary, New Zealand, Poland, Mexico, Ecuador, Brazil, Pakistan, Bangladesh, Thailand, Vietnam, Malaysia, Indonesia, Singapore, Philippines, Sri Lanka, India, UAE, Saudi Arabia, Qatar, Kenya, Ghana, Ethiopia, Somalia, Nigeria, South Africa, Swaziland, Mongolia etc.

BPM is not only manufacturing best quality geosynthetics products but also providing professional design and installation service. OEM, ODM, custom development and fabrication are also available. If you have any questions or inquiries, please fill and submit the following form, we will reply as soon as possible.