The black HDPE impermeable geomembrane liner cover for biogas digester improves the efficiency of biogas fermentation by relying on black geomembrane to absorb heat. The principle of biogas production is the same as that of a traditional biogas digester. It uses the advantages of HDPE geomembrane to prevent leakage. Lay a layer of HDPE impermeable geomembrane liner on the dug soil in the pit, the slag extraction pipe and the biogas collection pipe are installed in the pond according to the anaerobic fermentation process for the water easily inlet and outlet. The bottom of the slag discharge pipe should be close to the bottom HDPE impermeable geomembrane liner. The gas pipeline of the biogas digester uses ø200mm PE pipe, which can withstand the pressure above 10kpa. Before installing the gas pipeline, check whether the gas pipeline is leaking, especially the buried gas pipeline. Anchor ditch is excavated 1.5m around the earth pit pond, the size of the anchor ditch is 1m*1m, and the limited internal and external corners are rounded and chamfered. After laying the HDPE base geomembrane, fill the plain soil with a thickness of 20cm. After the top geomembrane is laid, fill the anchor trench with plain soil and ram. Cover the HDPE impermeable geomembrane to seal it, and then anchor the ditch to fix the geomembrane to form an integral anaerobic fermentation space.

HDPE geomembrane is made of high-quality polyethylene virgin material, the main component is high-density polyethylene, carbon black, anti-aging agent, antioxidant, ultraviolet absorber, stabilizer and other auxiliary materials, using the advanced fully automatic geotechnical production equipment, made by three-layer co-extrusion technology. All BPM HDPE impermeable geomembrane products are produced in accordance with American GRI standards and ASTM test standards, so how should the biogas digester geomembrane be selected? As for biogas digester geomembrane, we generally use 1.0mm thick geomembrane as the bottom membrane, and the standard is not lower than the national standard. If the biogas digester geomembrane cover, you should choose the urban construction standard geomembrane to ensure safety and service life. Its thickness should no less than 1.5mm. It is recommended to use 1.0mm geomembrane for the sedimentation tank geomembrane. The black membrane anti-seepage membrane biogas digester at the bottom of the biogas digester adopts anti-seepage geomembrane materials, and the anti-seepage membrane uses non-toxic environmental protection materials. The principle of self-defense is a physical process. The whole process does not produce toxic substances and does not affect land reuse. Moreover, the relatively low cost effectively replaces conventional materials (such as concrete, steel plates, bricks, etc.) to solve environmental problems such as shortage of construction materials, high prices, and dust, so as to comply with current environmental protection requirements. Black film biogas digesters can also solve the problems of water leakage and gas leakage caused by shrinkage, expansion and cracking of other types of biogas digesters due to temperature changes; it can also solve steel plate corrosion, pipeline blockage, equipment damage, and operation of steel plate biogas. The problem of high cost. However, the disadvantage of the black film biogas digester is that it occupies a relatively large area. If the generated biogas is to generate electricity, an anti-corrosion and explosion-proof supercharger must be added. Increase its safety factor.

Construction of HDPE Impermeable Geomembrane for Biogas Pool Project in Thailand

- Before cutting the geomembrane, the relevant dimensions should be accurately measured, and then cut according to the actual size. Generally, it is not advisable to cut according to the size shown in the figure. It should be numbered piece by piece and recorded in detail on the special form.

- When laying geomembrane, we should try to minimize the number of welds, and save raw materials as much as possible on the premise of ensuring quality. At the same time, it is easy to guarantee the quality.

- The overlap width of the seam between the HDPE impermeable geomembrane liner is generally not less than 10cm, and the welding seam is usually arranged in parallel to the maximum slope, that is, along the slope direction.

- Usually in corners and deformed areas, the length of the joints should be as short as possible. Except for special requirements, on slopes with a slope greater than 1:6, within 1.5 meters from the top slope or stress concentration area, there should be no welds as far as possible.

- When laying the geomembrane, avoid artificial wrinkles. When the temperature is low, it should be stretched and flattened as much as possible.

- After the geomembrane is laid, it is necessary to minimize walking and moving tools on the surface of the membrane. Anything that can cause harm to the impermeable membrane should not be placed on the membrane or carried on the membrane to avoid damage to the membrane. Cause accidental damage.

Advantages of BPM geomembrane in biogas digester project

Smooth HDPE impermeable geomembrane liner is designed and made of high quality polyethylene resin with proportional carbon black antioxidant, anti-aging and UV-resistance materials which exhibit impermeable and ultraviolet resistance properties. Compared with traditional concrete and compacted clay, smooth geomembranes have proven to be more cost effective, safe and fast deployment. And it can be anti-static treatment, it is very suitable for biogas digester project.

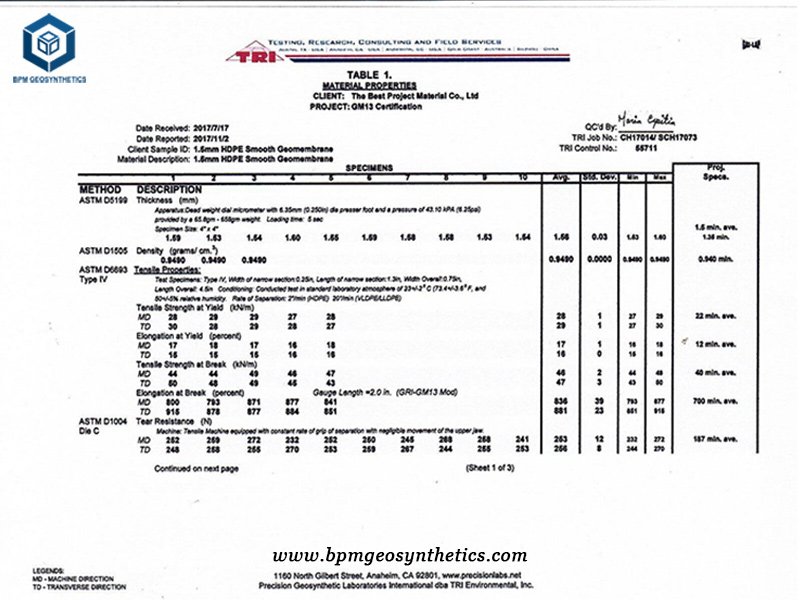

The Thailand customers contacted us through website, and hoped that the BPM team would provide biogas digester construction plans and HDPE impermeable geomembrane products. Taking into account the project specifications and environmental protection, our engineer suggested that he use GM-13 standard HDPE geomembrane with thickness of 1mm and 1.5mm, the cover of the biogas digester should use a pond lining with a thickness of 1.5mm, and the paving ground should use a pond lining with a thickness of 1mm. board. BPM also sent engineers to guide the construction at the customer’s project site. The customer was very satisfied with the service of the BPM team and the quality of the biogas digester.

Polyethylene geomembrane for Biogas Pool Project Specifications

- 1mm and 1.5mm geomembrane quantity – 23700 square meters

- Geomembrane specification – 7m*100m/roll

About BPM

BPM has been specializing in delivering one stop geosynthetics products and solutions to worldwide customers since its foundation in 2007. BPM had provided many types of effective and state of the art geomembranes, geotextiles, geocells, geosynthetic clay liners (GCLs), drainage boards, geogrids to over 81 countries. Our main customers are from Australia, France, Sweden, UK, Hong Kong, Hungary, New Zealand, Poland, Mexico, Ecuador, Brazil, Pakistan, Bangladesh, Thailand, Vietnam, Malaysia, Indonesia, Singapore, Philippines, Sri Lanka, India, UAE, Saudi Arabia, Qatar, Kenya, Ghana, Ethiopia, Somalia, Nigeria, South Africa, Swaziland, Mongolia etc.