The geotextile and geomembrane are the widely used geosynthetic material for civil engineering projects. Geotextile fabric is permeable fabrics which, when used in association with soil, have the ability to separate, filter, reinforce, protect or drain. Geomembrane is a polymeric membrane that constitutes a flexible, watertight material with a thickness of one-half millimeter or more. The geotextile and geomembrane can be used together to form a systematic solution for slope protection, heap leach pads, embank reinforcement projects, etc.

Case Study

- Location: Mongolian Mesopotamia

- Product: 1.5mm Geomembrane and 300GSM Nonwoven Geotextile

- Application: Fluorite Heap Leach Pads and Reservoir

Issue

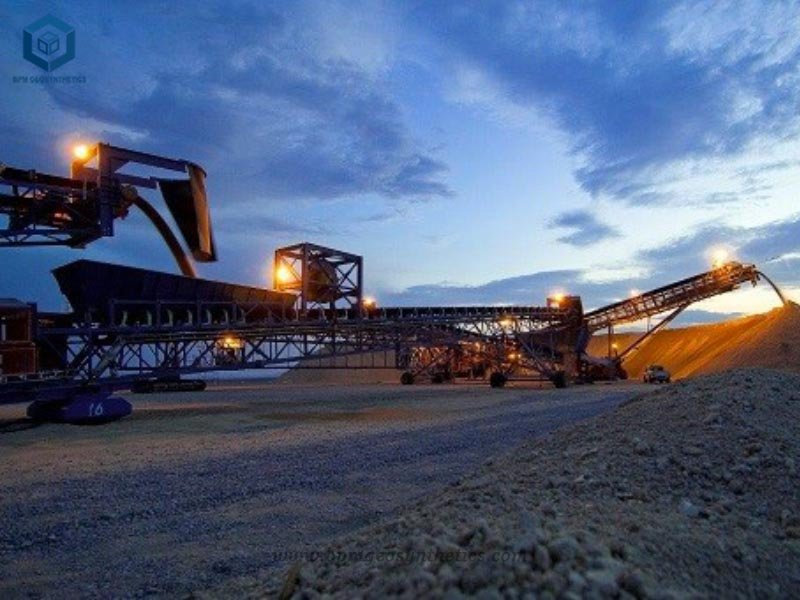

A domestic construction group got a fluorite mine currently being mined in Ershile Sumu, Gobi Province, Mongolia. Fluorite is widely applied in the aluminum industry, ceramics, aerospace parts, cement manufacturing and other industries. The company invested and developed this mining production in Mongolia. This mine is located in a relatively remote part in Mongolia, and the water and electricity transportation is not convenient to get. A heap leaching pond is necessary in the process of mineral mining, and a clean water reservoir must be built to allow wastewater to be recycled and reused to solve the problem of water use. The ore is placed on a heap leaching pad lined with geotextile and geomembrane, and the ore-rich solution is discharged into the reservoir through the lined ditch. Mongolia has strict protection of groundwater, so the geomembrane must achieve good anti-seepage effect and avoid heavy metal pollution to groundwater, and the geotextile as the separation layer to protect the geoemembrane from puncture.

The project is divided into two projects and phases, the first isclean water tank and the second is heap leaching tank. Due to lack of a professional geomembrane construction welding team and equipment in Mongolia, the customer asked us to undertake a full package service of geomembrane materials and construction.

Solution

In the first step, the customer gave us their engineering design drawings and CAD, and our engineers calculated the reasonable thickness and application quantity of geotextile and geomembrane based on their CAD drawing. The two parties’ negotiation and accounting finally reached a reasonable number of applications. Finally choose 1.5mm smooth HDPE Geomembrane and 300gsm double-layer PET nonwoven geotextile as the base materials。

In the second step, the Mongolian government as a third-party supervision department,always supervise the selection of geomembrane and geomembrane and final construction approval , and there is a very strict procedures.

The third step is to inspect the factory. Customers have repeatedly inspected our geotextile and geomembrane production process and bulk goods before finally reaching a consensus on cooperation.

The fourth step is to cooperate with the domestic professional welding team to complete the construction welding of the fluorite mine. The construction team undertakes the construction of the national tailing ponds,hydropower stations and large-scale waste landfill, equipped with imported welding equipment from Switzerland, professional and responsible.

In the fifth step, after we delivered the geotextile and geomembrane to the construction site through Erlian port, our construction team arrived following on, which took 3 months to complete.

Benefits

- Long-term durability. Durability and high chemical resistance are ensured by carefully selected resins and a special stabilising system, which is aligned with the resin type. An enormous amount of field and lab data supports this performance.

- High durability HDPE Liner. Functional waterproofing is an important criterion for a geomembrane. Aging and inadmissible stresses endanger this function. BPM HDPE geomembranes have a high durability, because they are manufactured from well-chosen resins with a very low stress crack resistance. These resins consist on hexene or octene copolymer. Testing with the Notched Constant Tensile Load Test according to DIN EN 14576 or ASTM D5397 verifies the high stress crack resistance of BPM geomembranes. Long term tensile tests, especially on structured material, prove the durability as well.

- Advantages

- Very high chemical and thermal resistance level.

- This type of installation has a very long service life.

- Costs are lower compared to other facilities.

- It is very resistant against possible impacts.

- Resistant to acids and most liquids. Also in the water up to about 100oC.

- The use of high-density polyethylene makes the geomembrane flexible even at low temperatures.

- Quality control is performed during the installation process.

- Compared to low-density polyethylene, it is stiffer.

Summary

The HDPE geomembranes are highly beneficial and widely used because of their manifold features. They are made of the material which is highly stable and because of this, the HDPE geomembranes are able to maintain long-term reliability and durability. The geomembranes are tailored products that can be customized as per the need of the customers. As the HDPE geomembranes follow the safety standards, they are the admired products of the clients. The HDPE membranes are hugely in demand because of their environmental friendly characteristics. These properties have made the HDPE geomembrane a standard choice to water-resistant, covered landfills and various containment uses.The geomembrane liners are extremely useful for vast projects and for the control of unsafe liquids that could pollute the surrounding if not enclosed correctly. The geomembranes are extensively used because of the numerous benefits and their chemical resistant properties. HDPE is one of the most comprehensively and commonly used geomembranes in the world due to its easy availability and reasonability. HDPE geomembrane is certainly an excellent product for large applications that require UV and Ozone resistance, chemical resistance or high-quality installations. All these benefits have made the HDPE geomembranes a popular choice among the customers.

Specifications of Geotextile and Geomembrane for Fluorite Heap Leach Pads Project in Mongolian

- Total HDPE liner quantity– 500,000 squares meters

- HDPE liner thickness – 1.5mm

- Each roll size is 7m*140m

- Total geoetxtile quantity–300,000 squares meters

- Geotextile specification– 300gsm

About BPM

BPM has been specializing in delivering one stop geosynthetics products and solutions to worldwide customers since its foundation in 2007. BPM had provided many types of effective and state of the art geomembranes, geotextiles, geocells, geosynthetic clay liners (GCLs), drainage boards, geogrids to over 81 countries. Our main customers are from Australia, France, Sweden, UK, Hong Kong, Hungary, New Zealand, Poland, Mexico, Ecuador, Brazil, Pakistan, Bangladesh, Thailand, Vietnam, Malaysia, Indonesia, Singapore, Philippines, Sri Lanka, India, UAE, Saudi Arabia, Qatar, Kenya, Ghana, Ethiopia, Somalia, Nigeria, South Africa, Swaziland, Mongolia, etc.