Drainage cell panels are the widely used drainage system for indoor and outdoor construction projects.

1 What is Drainage Cell Panels?

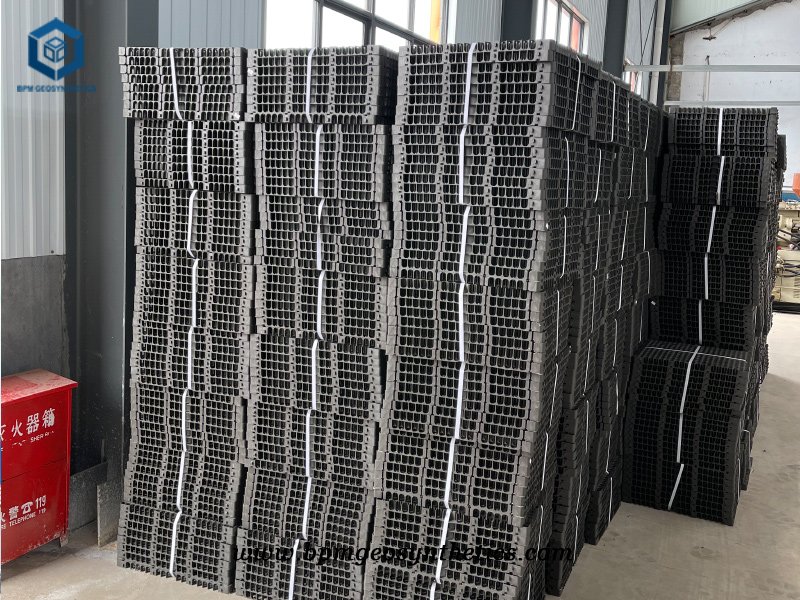

Drainage cell panels are innovative structures made from HDPE or PP materials. These panels undergo a heating, pressurization, and molding process to create a unique shape. They are then wrapped in a filtration geotextile, enabling the creation of a drainage channel with a three-dimensional space that provides support and allows water retention.

These drainage cell panels have a wide range of applications, including roof gardens, roof drainage systems, basements, pond filtration systems, culverts, drainage ditches, and sports fields. During construction, the drainage cell panels are pressed onto flat surfaces such as basement walls, underground footings, and roofs. They offer long-term compression resistance, withstanding the weight and load of concrete floors, as well as external pressures and impact forces encountered during construction activities, such as vehicle impact and concrete pouring.

The use of drainage cell systems introduces several benefits. It enables cement-free mortar construction, resulting in lower project costs. The system provides efficient drainage with no blockages, contributing to its overall effectiveness. Furthermore, the drainage cell material is reusable, requiring minimal maintenance after construction, which leads to lower operating costs. The combined drainage cell surface can also be landscaped, allowing for a seamless integration with the surrounding environment. It helps prevent soil erosion and promotes an eco-friendly and energy-saving approach.

In summary, drainage cell panels offer a versatile and effective solution for managing water drainage in various applications. Their unique design, durability, and environmental benefits make them an ideal choice for construction projects seeking efficient drainage systems.

2 Case Study of Drainage Cell Panels for Stadium Roof Project in Thailand

- Construction location – Bangkok, Thailand

- Products used – 30mmX500mmX500mm PP drainage cell panels

- Construction area – 4000 square meters

- Application project – Roof drainage system of indoor stadium

3 Why Chose Drainage Cell Panels Thailand for Stadium Roof Project

Our customer in Thailand chose drainage cell panels for their stadium roof project due to several compelling reasons. When the customer reached out to us with their inquiry, they specifically requested drainage cell products with high compressive strength and excellent load-bearing capacity for their indoor stadium’s roof drainage system.

In response, we promptly provided the customer with a comprehensive quotation, detailed parameters, and a test report specifically for the 30mmX500mmX500mm drainage cell panels they required. The customer expressed interest in obtaining a sample, requesting 1 square meter of drainage cell products. Understanding the urgency, we swiftly arranged for the delivery of 4 square meters of samples the following day.

Upon receiving the samples, the customer conducted thorough testing, focusing on aspects such as compressive strength and other relevant indicators. They expressed satisfaction with the quality of our products, which further solidified their confidence in our offerings. Additionally, the customer shared the construction site drawings with us, allowing our technicians to calculate the required product area, which amounted to approximately 4000 square meters.

Subsequently, we engaged in detailed discussions with the customer regarding loading methods, packaging, and pricing. These conversations led to the formulation of a contract that met the customer’s specific requirements. Once the customer made the necessary payment, we swiftly initiated the production process to fulfill their order.

Choosing drainage cell panels from us for their stadium roof project was a result of the customer’s trust in our product quality, prompt response, and efficient service. We are committed to delivering on our promises and ensuring the successful implementation of their project. As we proceed with production, we remain dedicated to meeting the customer’s expectations and providing them with a reliable and high-quality solution for their stadium’s roof drainage needs.

4. Main advantages of Drainage Cell Panels

Drainage cell panels offer a comprehensive solution for effective water management, structural protection, and improved construction performance. Their versatility, strength, and easy installation make them a valuable choice for a wide range of applications. Drainage cell panels offer several main advantages that make them a preferred choice in various applications:

4.1 Efficient Water Discharge

The installation of drainage cell panels enables quick and effective drainage of rainwater. This reduces or eliminates hydrostatic pressure on the waterproof layer. The active water guiding principle of drainage cells promotes effective waterproofing.

4.2 Versatile Functionality of Drainage cell panels

When combined with geotextile, drainage cell panels offer multiple functions such as drainage, waterproofing, ventilation, moisturizing, and partitioning. This versatility allows for comprehensive solutions in various construction scenarios.

4.3 Lightweight and High Strength of Drainage cell panels

Drainage cell panels are lightweight, making them easy to handle and transport. Despite their light weight, they possess high structural strength, ensuring durability and stability in demanding conditions.

4.4 Moisture Insulation and Heat Insulation

The multiple fulcrums of drainage cell panels create a gap between the building surface layer and the structural layer. This arrangement provides moisture insulation, drainage, and heat insulation capabilities, enhancing the overall performance of the construction.

4.5 Protection of Structural and Waterproof Layers

One of the key benefits of drainage cell panels is their ability to effectively protect the structural layer and the waterproof layer of a construction project. By preventing damage to these crucial elements, the longevity and integrity of the building and waterproofing system are ensured.

4.6 Effective Water Discharge

The design of drainage cell panels includes large and small pivots along the edges. These pivots can interlock with each other, creating a continuous slope. This design allows for efficient and timely discharge of excess water, even under heavy water leakage conditions.

4.7 Simple Construction and Transportation

Drainage cell panels are designed for ease of use in construction projects. They are simple to install and transport, saving time and effort during the construction process.

Drainage cell is a widely used geotechnical material for water drainage applications. The drainage cell panels have a lightweight three-dimensional structure and is pressed on the underground structure (such as basement wall or underground foundation) for groundwater management. The drainage cell is specially produced with a flat back, which can form a permanent, non-clogging gap between the concrete slab and the soil profile. Compared with the small voids created by the use of geocells, the void space of the drainage cell can achieve superior drainage efficiency. The pressure of the backfilled soil holds the drainage unit in place.

5 Construction Steps of Drainage Cell Panels

- Clean up the rubbish at the paving site and level the cement so that the site has no obvious bumps. The roof of the outdoor garage and the roof garden need to have a slope of 2-5‰.

- The roof greening and outdoor garage roof greening can be equipped with porous water pipes, so that the water discharged from the drainage cell can be discharged to the nearby sewers or nearby urban sewers.

- The basement floor is anti-seepage water, and the floor is raised above the foundation, that is, a layer of drainage cell is made before the floor is made. The round protruding platform is downward, and there are blind ditches around, so that the groundwater cannot come, and the seepage can pass through naturally. The space of the drainage cell flows into the surrounding blind ditch, and then flows into the sump through the blind ditch.

- Anti-seepage of the basement wall. Drainage cell can be laid on the main wall of the building, the round protruding platform faces the main wall, and a layer of single wall is built outside the drain cell or steel mesh powder cement is used to protect the drain cell. The space of the seepage plate outside the wall flows straight down into the blind ditch to the sump.

- When laying drainage boards in any section, care must be taken not to let dirt, cement, yellow sand and other garbage enter the front space of the drainage cell to ensure that the drainage board space is unblocked.

- When laying the drainage cell, take protective measures as much as possible. When laying the drainage cell on the floor or outdoor garage, backfill should be done as soon as possible to prevent the high wind from disturbing the drainage cell and affect the laying quality; the waterproofing of the basement and internal walls should be protected as soon as possible Layer to prevent the drain cell from being damaged by people or objects.

- The backfill is cohesive soil. It is ideal to lay 3-5 cm yellow sand on the geotextile, which is beneficial to the filtration of the geotextile; if the backfill is a nutrient soil or light soil, there is no need to lay another one. Layers of yellow sand, this kind of soil itself is very loose and easy to filter water.

- When laying the drainage cell, lay the next 1-2 fulcrums on the side and the right side. You can also touch the two bottom plates, and use geotextiles to lap the top. As long as there is no soil entering the drainage channel of the drainage cell, you can keep the drainage smooth.

About BPM

BPM has been specializing in delivering one stop geosynthetics products and solutions to worldwide customers since its foundation in 2007. BPM had provided many types of effective and state of the art geomembranes, geotextiles, geocells, geosynthetic clay liners (GCLs), drainage boards, geogrids to over 81 countries. BPM is not only manufacturing best quality geosynthetic products but also providing professional design and installation service. OEM, ODM, custom development and fabrication are also available. If you have any questions or inquiries, please contact us.