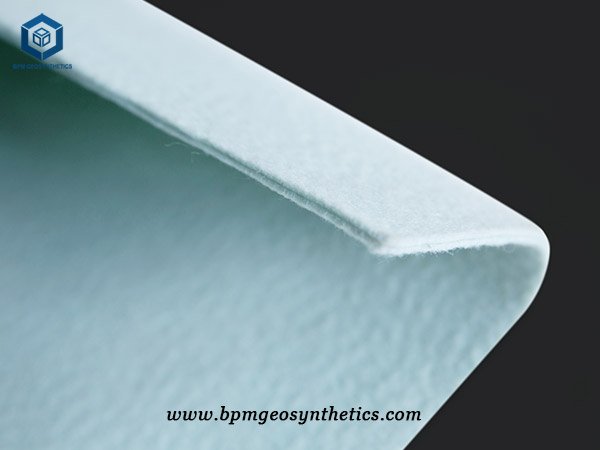

Composite geomembrane lining system, also known as composite geomembrane, is the kind of geosynthetic product combined of geotextile (base fabric can be filament or short fiber needle punched geotextile, woven geotextile) with geomembrane by heat bonding processing process. It remains the mechanical properties of base fabric and uniformity of geomembrane which improved the impermeability. Embossed processing on the geomembrane strengthens its friction coefficient, stability and easy for installation. Composite geomembrane lining system has the functions and advantages of both geotextiles and geomembranes. The geotextile layer increases essential tensile strength and the geomembrane layer provides excellent impermeable, leak and moisture proof, so the composite geomembrane lining system is a multi-function anti-leakage membrane liner with high tensile strength, reinforcement, separation, drainage, tear resistance, protection, etc.

The composite geomembrane is often divided into one geotextile with one geomembrane and one geomembrane with two geotextiles. Generally, the composite geomembrane lining system has the width of 4-6m with weight of 400-2000g/m2, it has high physical and mechanical properties such as tensile strength, and slip resistance and bursting which can meet the civil engineering needs such as construction, water conservancy, municipality, transportation, subway, tunnels, etc. It also can be used in unconventional high temperature environment because polymer materials and anti-aging agent is added to the production process. The composite geomembrane is the ideal permeable geotechnical material which is widely used for landfills, waste water treatment, roads construction, aquaculture, landscape and agriculture, etc.

As the professional geomembrane and geosynthetics manufacturer and wholesaler, The Best Project Material Co., Ltd (BPM Geosynthetics) has been dedicated to supplying one stop geomembrane and geosynthetics to worldwide customers since its foundation in 2010. Our geosynthetic products include geomembrane, geotextile, geocell, geosynthetic clay liner (GCL), drainage board, geogrid, etc. All BPM geosynthetics has been certificated by the ISO9001, ISO14001, Soncap, SASO and BV certificates and passed the test of SGS and Intertek etc. BPM geosynthetic products are widely used across a variety of industries including waste containment, water containment, aquaculture, industrial project, energy project and mining project, etc.

Mining industry is often found to be the single largest producer of solid objects like mining ore and tailings around the world. Waste rock and tailings are two primary forms mining waste. The composite geomembrane lining system is used to prevent chemical solution from dissolved minerals from ore, and to allow the leachate to be collected and refined. The mining facilities are subjected to moderate to high loads, composite geomembrane lining system materials are often used to preventing leakage and corrosion from mining ore and waste. BPM is the proven composite geomembrane lining system supplier for mining industry.

Gécamines SA is the state-controlled corporation (a contractor of the title La Générale des Carrières et des Mines) who explores, researches, exploits and produces various mineral products with side deposits. Gécamines SA is also involved in securities and property within the commercial, industrial and financial sectors, as well as development activities in farming and agriculture. Gécamines SA is also the largest mining company in the DRC, one of the largest in Africa, and owns the world’s largest deposit of cobalt. Gécamines SA produced 500,000 tonnes of copper a year during the 1980s, and has since then plays a significant role in the field of copper mining. Gécamines SA is situated in the Katanga Province, which is rich in mineral deposits, Gécamines has partnered with companies such as Anglo-Swiss, Glencore International, Freeport-McMoran, and Eurasian Natural Resources Corporation.The mining project of Gécamines SA requires much higher standard composite geomembrane lining system to contain the leach-ate and waste material generated in the mining processes.

Gécamines SA found us through google search on February 6, 2019, they sent BPM team the composite geomembrane lining system specifications for this mining project. And they sent the professional engineers to visit BPM factory to check composite geomembrane lining system manufacturing processes and the quality of composite geomembrane. They gave us urgent schedule and delivery time for 50,000 square meters composite geomembrane lining system product with BV Inspection. Within 7 days, BPM got payment from Gécamines SA.

They also ordered 10 containers of HDPE pipe. After 2 weeks, all ordered composite geomembrane lining system products for Gécamines SA has passed 6 anchor trench of the third party BV company and were arranged for shipment.

Specifications of Composite Geomembrane Lining System for Mining Project in Congo

- Total quantity – 50,000 square meters

- Specification – two layer 300g/㎡ nonwoven geotextile+ one layer 1.5mm geomembrane

- Each roll size – 5.8m*50m

- Rolls – 173

- Inspected by BV

7 Considerations for Composite Geomembrane Installion

1. In the construction, firstly, the sand surface or the clay with a smaller diameter should be used to level the base surface, and then the composite geomembrane lining system are installed. The composite geomembrane should not be stretched too tightly, and the soil embedded in the soil at both ends is corrugated. Finally, a layer of about 10 cm is layered with fine sand or clay on the geomembrane. A 20-30cm block stone (or prefabricated block) is placed as an impact protection layer. During construction, try to avoid the stone directly contact the geomembrane. It is best to carry out the construction of the protective layer while laying the composite geomembrane lining system. The joint of the composite geomembrane lining system and the surrounding structure shall be anchored by expansion bolts and steel strips, and the joints shall be coated with emulsified asphalt (thickness 2mm) to prevent leakage.

2. The contact surface between the composite geomembrane and the supporting material should be leveled to avoid the geomembrane being pierced and lose its anti-seepage effect even with a layer of geotextile. Otherwise, a fine grain cushion should be provided to protect the film from damage.

3. Usually in the corners and deformed sections, the length of the joint between the composite geomembrane lining systems should be as short as possible, except for special requirements, try not to weld in the slope of the slope greater than 1:6 from the top slope or stress concentration area within 1.5 meters.

4. The connection of the composite geomembrane lining system itself, the connection mode of the anti-seepage geomembrane can be summarized into three types, namely, bonding method, welding method and vulcanization method, which are selected according to different raw materials of the anti-seepage geomembrane, and impermeability of all joint seams. All should be inspected to prevent leakage and joint leakage. Automatic HDPE liner welding machine is often ideal equipment to realize HDPE geomembrane welding seams.

5. The connection of the gcomposite geomembrane lining system to the surrounding boundary. The composite geomembrane lining system and the surrounding boundary must be tightly combined. During construction, the anchoring trench can be excavated on the foundation and the bank slope. If the foundation is a shallow sand gravel permeable layer, the gravel should be excavated until the bedrock is poured and then the concrete base is poured. The composite geomembrane lining system is fixed in the concrete. If the foundation is impervious to water, the anchor trench with a depth of 2m and a width of about 4m can be excavated, the composite geomembrane is placed in the trough, and then the clay is densely backfilled; if the foundation is deep, the gravel permeable layer can be impervious by HDPE geomembrane coating. The length is determined according to the calculation. The covering part must be leveled, and the transition layer with a thickness of about 30cm and a maximum diameter of 20mm should be laid. The filter layer is then provided with a protective layer. The periphery of the geomembrane liner should be tightly combined with the impermeable layer on both banks of the bank. The connection between the barrier geomembrane and the anchor trench is determined by the allowable contact osmosis slope of the geomembrane and concrete. Polyvinyl chloride and butyl rubber films can be adhered to the concrete surface with a binder or a dissolving agent, so the embedding length can be shorter, because the HDPE geomembrane can not adhere to the concrete surface, so at least 0.8m of the length of the concrete is embedded.

6. After the composite geomembrane is laid, the walking and moving tools on the composite geomembrane lining system surface should be minimized. Any objects that can cause damage to the impermeable geomembrane should not be placed on the membrane or carried on the membrane to avoid the geomembrane caused accidental damage.

7. Be careful to stack the first layer of mining ores on the composite geomembrane in accordance with the working rules. The mining ores are easily to break the geomembrane even with the upper layer of geotextile.

BPM has been exported many geosynthetic products for mining operations to Africa and South America. With millions of square meters of composite geomembrane lining system installed, BPM geosynthetics has been approved with the highest quality to meet the requirements for the mining industry. We are also providing professional design and installation service.

For the mining projects, GAI LAP testing and third party testing is always required. BPM can fully comply with or exceed the requirement of mining industry standard.

About BPM

BPM have provided many types of effective and state of the art geomembrane, geotextile and geosynthetics products to over 36 countries. Our main innovative, high quality geosynthetics products include geomembrane, geotextiles, geocell, geosynthetic clay liners (GCLs), drainage boards, geogrids, etc. BPM brand brand high quality geosynthetic products had been certificated by the ISO9001, ISO14001,OHSAS18001 Soncap, SASO and BV, SGS and Intertek, etc.

BPM is also providing professional design and installation service. OEM and ODM are also available. If you have any questions or inquiries, please fill and submit the following form, we will reply as soon as possible.