Composite drain netting, also knwon as composite drain net, is the kind of drainage products made from geonet bonding two layer of geotextile which combines the properties of geotextile filtration and geonet drainage and protection. The composite drainage net provides complete “Inverted filter-drainage to product” effect. Composite drainage netting is effective at reducing foundation settlement.

As the leading geosynthetics manufacturer and supplier, BPM Geosynthetics offers a wide range of drainage products with custom thickness and size at best factory price.

1. What Is Composite Drain Netting?

Composite drain netting, made of plastic core and non-woven fabric, outperforms traditional drains. It resists clogging, ensuring water flow. The netting’s plastic side can be glued to walls, reducing hydrostatic pressure. Available in large rolls, it can be shipped coast-to-coast. The net captures pollutants in stormwater systems. Attached to drainage pipes, it filters water before release. This prevents pollution and protects the environment. Composite drain nets stabilize foundations and prevent settlement. Made from HDPE with additives, the net’s structure promotes vertical drainage. In Indonesia, improving infrastructure is key for economic growth. Road projects boost connectivity and business. Transportation supports global trade.

2. What Are Benifits of Composite Drain Netting Product for Roadbed Project?

Composite drain netting provides a reliable, durable, and cost-effective solution for roadbed projects, ensuring efficient drainage and long-term stability. BPM composite drain netting offers several benefits for roadbed projects:

2.1 Strong Drainage Ability

The combination of geonet and geotextile in composite drain netting provides excellent drainage capabilities. It allows for efficient water flow, preventing water accumulation and ensuring the stability of the roadbed.

2.2 High Tensile Strength

Composite drain netting is designed to withstand high tensile forces, making it durable and resistant to deformation. This strength helps maintain the integrity of the roadbed, even under heavy loads.

2.3 High Chemical Resistance Stability

The materials used in composite drain netting exhibit high resistance to chemicals, ensuring long-term stability and performance in various environmental conditions.

2.4 High Friction Coefficient

The composite drain netting has a high friction coefficient, which enhances its ability to grip the surrounding soil or aggregate layers. This helps prevent slippage and displacement, ensuring the stability of the roadbed.

2.5 Reliability

The multi-directional core configuration of composite drain netting provides a uniform flow path for water, ensuring consistent and proven long-term performance. This reliability contributes to the overall effectiveness of the drainage system.

2.6 Pressure Relief

Composite drain netting helps relieve hydrostatic pressure buildup against subterranean surfaces. By allowing water to escape efficiently, it reduces the risk of damage to the roadbed caused by excessive pressure.

2.7 Drainage Capacity

The high-flow drainage capacity of composite drain netting is significantly greater than that of traditional aggregate or sand. It can handle up to three times the flow capacity, ensuring effective drainage for various drainage needs in roadbed projects.

2.8 Cost Efficiency

The lightweight and easy-to-install panels of composite drain netting (typically measuring 1.22m x 15.24m or 4′ x 50′) offer cost savings compared to traditional methods. It eliminates the need for transporting large quantities of aggregate to the construction site, reducing transportation costs.

3. How Does Composite Drainage Netting Work?

Composite drain nets catch debris and pollutants in stormwater. They trap items like packaging and leaves, stopping them from entering the system. This reduces pollution and safeguards the environment. The nets hold a lot of debris and are easy to clean, ensuring efficient drainage. Made from strong polypropylene, they resist damage even in fast water flow. This design prevents clogs and maintains water quality. Composite drain nets improve drainage systems’ efficiency and durability, promoting environmental protection.

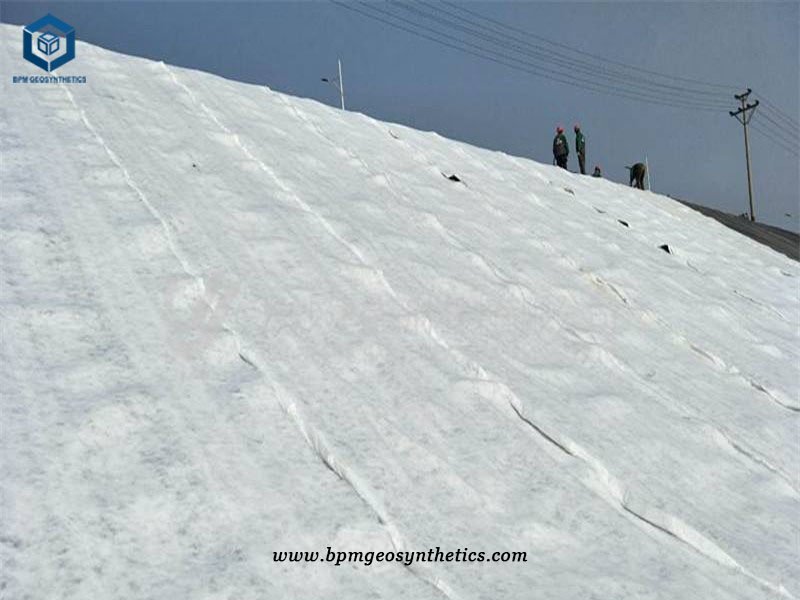

4. Case Study of Composite Drain Netting Product for Roadbed Project in Indonesia

In Jakarta, a client needed better drainage for a new highway. They got a composite drain net with 6mm thickness and 200g geotextile after testing a sample. This 30,000 square meter order had rolls 2m by 30m for easy installation. The drain net’s three layers included a central rib for drainage and support ribs for stability under heavy loads. It was great for various projects like roads and tunnels. For soft soils or high water tables, a sand layer at the base is advised, but if sand is scarce, a geocomposite layer can be used. This saved embankment height, provided good drainage, and was cost-effective. Using this drain netting improved the highway’s drainage, ensuring its stability and long life.

5. About BPM Geosynthetics

BPM Geosynthetics has been specializing in delivering one stop geosynthetics products and solutions to worldwide customers since its foundation in 2007. BPM had provided many types of effective and state of the art geomembranes, geotextiles, geocells, geosynthetic clay liners (GCLs), drainage boards, geogrids to over 81 countries.

If you have any questions or inquiries, please contact us, we will reply as soon as possible.