Composite drain netting, also knwon as composite drain net, is the kind of drainage products made from geonet bonding two layer of geotextile which combines the properties of geotextile filtration and geonet drainage and protection. The composite drainage net provides complete “Inverted filter-drainage to product” effect. Composite drainage netting is effective at reducing foundation settlement.

As the leading geosynthetics manufacturer and supplier, BPM Geosynthetics offers a wide range of drainage products with custom thickness and size at best factory price.

1. What Is Composite Drain Netting?

Composite drain netting is an innovative drainage geotechnical material that combines a plastic three-dimensional core with non-woven geotextile fabric. This type of drainage product offers superior performance compared to traditional gravel-based drains or non-three-dimensional products. The inner drainage chamber of the composite drain netting is protected from debris and resistant to clogging, allowing for efficient water flow.

The composite drain netting features a fabric side and a plastic side. The plastic side can be easily attached to foundation walls using standard construction adhesives. Its high compressive strength also helps alleviate hydrostatic pressure buildup against subterranean surfaces, making it beneficial for relieving pressure on foundations. The composite drain netting is typically available in rolls measuring 4′ x 50′, and it can be shipped from warehouses located on both the east and west coasts to ensure timely delivery.

These drain nets serve as primary treatment devices, capturing large gross pollutants that may migrate through the stormwater system. They are attached to piped drainage outlets, forcing stormwater to pass through the netting as it exits the drainage pipe. This helps prevent the release of pollutants into the environment.

Composite drainage nets are particularly effective in reducing foundation settlement, providing stability and protection to infrastructure.

The drain netting core is made of high-density polyethylene raw materials, which are enhanced with carbon black, ultraviolet stabilizers, and antioxidant stabilizers. The interlaced net structure forms a drainage channel with excellent vertical drainage properties.

In Indonesia, infrastructure construction has been relatively lagging behind the country’s vast territory, which poses a significant constraint on economic growth and investment environment improvement. Strengthening infrastructure construction has become a major initiative of the local government and a crucial factor in ensuring long-term economic growth in Indonesia. Roads and highways receive significant investment, driven by rising prosperity and the need for improved connectivity between towns and facilitation of business activities. The transportation and logistics industry plays a crucial role in supporting global product supply chains and is considered the backbone of modern trade.

2. What Are Benifits of Composite Drain Netting Product for Roadbed Project?

Composite drain netting provides a reliable, durable, and cost-effective solution for roadbed projects, ensuring efficient drainage and long-term stability. BPM composite drain netting offers several benefits for roadbed projects:

2.1 Strong Drainage Ability

The combination of geonet and geotextile in composite drain netting provides excellent drainage capabilities. It allows for efficient water flow, preventing water accumulation and ensuring the stability of the roadbed.

2.2 High Tensile Strength

Composite drain netting is designed to withstand high tensile forces, making it durable and resistant to deformation. This strength helps maintain the integrity of the roadbed, even under heavy loads.

2.3 High Chemical Resistance Stability

The materials used in composite drain netting exhibit high resistance to chemicals, ensuring long-term stability and performance in various environmental conditions.

2.4 High Friction Coefficient

The composite drain netting has a high friction coefficient, which enhances its ability to grip the surrounding soil or aggregate layers. This helps prevent slippage and displacement, ensuring the stability of the roadbed.

2.5 Reliability

The multi-directional core configuration of composite drain netting provides a uniform flow path for water, ensuring consistent and proven long-term performance. This reliability contributes to the overall effectiveness of the drainage system.

2.6 Pressure Relief

Composite drain netting helps relieve hydrostatic pressure buildup against subterranean surfaces. By allowing water to escape efficiently, it reduces the risk of damage to the roadbed caused by excessive pressure.

2.7 Drainage Capacity

The high-flow drainage capacity of composite drain netting is significantly greater than that of traditional aggregate or sand. It can handle up to three times the flow capacity, ensuring effective drainage for various drainage needs in roadbed projects.

2.8 Cost Efficiency

The lightweight and easy-to-install panels of composite drain netting (typically measuring 1.22m x 15.24m or 4′ x 50′) offer cost savings compared to traditional methods. It eliminates the need for transporting large quantities of aggregate to the construction site, reducing transportation costs.

3. How Does Composite Drainage Netting Work?

Composite drainage netting works by effectively trapping and capturing various debris and pollutants as stormwater flows through the nets. Items such as food packaging, cans, leaves, sediments, and other organic matter are caught within the netting, preventing them from entering the stormwater system. This helps to reduce pollution and protect the environment.

The nets are designed to have a high capacity for holding debris. Once the nets become full, they can be easily detached and emptied, allowing for convenient maintenance and cleaning. This ensures that the drainage system continues to function efficiently.

Composite drainage netting is constructed from high-tenacity polypropylene, which provides excellent durability and strength. This material allows the nets to withstand robust water flow without being damaged or torn. Even in areas with high water velocity, the netting remains intact, ensuring its long-lasting performance.

The design and construction of composite drainage netting make it an effective solution for managing stormwater runoff. By capturing and containing debris, it helps to prevent clogging and blockages in the drainage system, ensuring the smooth flow of water. It also contributes to maintaining water quality by reducing the presence of pollutants in the stormwater.

Overall, composite drainage netting plays a vital role in improving the efficiency and effectiveness of drainage systems, promoting environmental protection, and ensuring the durability and longevity of infrastructure.

4. Case Study of Composite Drain Netting Product for Roadbed Project in Indonesia

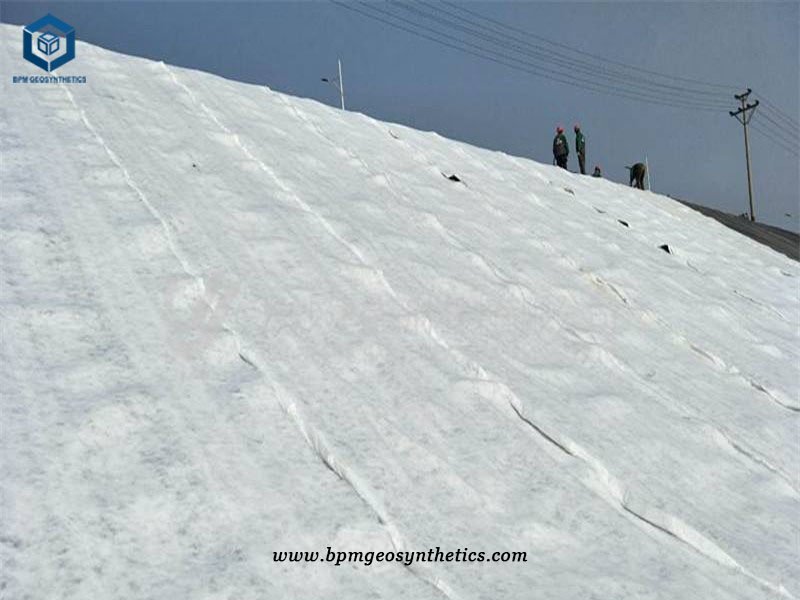

In Indonesia, a client embarked on the construction of an intercity highway in Jakarta and sought a solution to enhance the drainage capacity of the roadbed. They approached a local contractor who, in turn, reached out to a partner for assistance. After discussing the technical requirements, a composite drain netting product was recommended, featuring a 6mm thickness and 200g filament geotextile. To ensure its suitability, a sample was provided to the customer for testing, which ultimately met their requirements and resulted in an order being placed.

The composite drain netting employed for this roadbed project in Indonesia had specific specifications. It had a thickness of 6mm, and a total quantity of 30,000 square meters was required. Each roll of the product measured 2m by 30m, facilitating efficient installation and coverage.

The composite drain netting utilized a three-layer structure with distinct functionalities. The central rib, arranged longitudinally, provided high rigidity and formed a drainage channel. The upper and lower ribs acted as supports, preventing the geotextile from sinking into the drainage channel and maintaining optimal drainage performance even under heavy loads. By utilizing a double-sided bonded water-seepage geotextile composite, the product exhibited comprehensive capabilities in filtration, drainage, breathability, and protection. Consequently, it was considered an ideal drainage material for various applications, including railway, highway, tunnel, municipal engineering, reservoir, and slope protection projects, where its effectiveness had been demonstrated.

In scenarios involving embankments over soft soils or areas with high water tables, it is recommended to incorporate a sand layer at the base of the embankment to prevent subgrade fouling and reduce excess pore water pressure. However, in cases where quality sand is scarce, a geocomposite layer can be utilized as a sandwiched alternative between two thinner layers of sand. This basal layer configuration offers benefits such as embankment height savings of up to 40%, high hydraulic and drainage properties, and a cost-effective and durable maintenance solution.

By employing composite drain netting in the roadbed project, the client in Indonesia was able to enhance the drainage capacity of the highway, ensuring stability, reducing maintenance needs, and providing a long-lasting solution to mitigate potential issues caused by soft soils and high water tables.

5. About BPM Geosynthetics

BPM Geosynthetics has been specializing in delivering one stop geosynthetics products and solutions to worldwide customers since its foundation in 2007. BPM had provided many types of effective and state of the art geomembranes, geotextiles, geocells, geosynthetic clay liners (GCLs), drainage boards, geogrids to over 81 countries.

If you have any questions or inquiries, please contact us, we will reply as soon as possible.