As the professional geosynthetics manufacturer and exporter, BPM has been dedicated to manufacturing and supplying high quality such geomembrane products as smooth geomembrane, textured geomembrane liner and composite geomembrane since its foundation in 2007.

The largest volumes of products of the oil and gas industry are fuel oil and gasoline. Oil and gas is the primary material for a multitude of chemical products including water treatment chemicals, refrigerant, pharmaceutical intermediates, cosmetic raw materials, abrasive polishing compound, food additives, adsorbents, paints and coatings, etc. The oil and gas industry carries out the global processes of exploration, extraction, refining, transporting, and marketing of petroleum products. As the oil and gas industry leader, Chevron had taken BPM HDPE textured geommebrane as the anti seepage lining system to protect the production environment of oil pits, pipelines and production processes from polluted , so the safe working conditions, environmental protection and economical production can be realized. BPM textured geomembrane liner is the ideal geotechnical lining material for all types of chemicals and fuel containment applications produced in the oil and gas industry.

1. What Is HDPE Textured Geomembrane Liner?

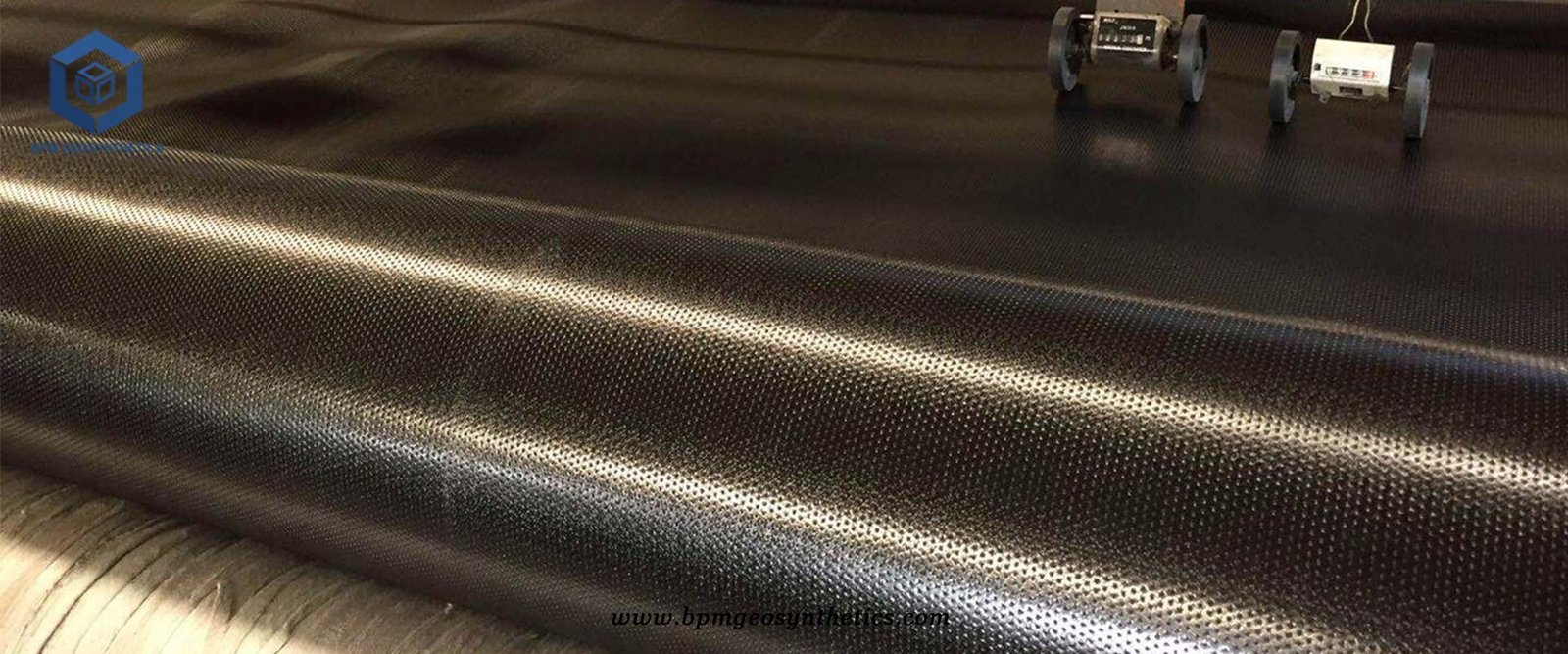

The HDPE textured geomembrane liner is a specialized liner that is created and manufactured using an automatic production process and optimized engineering techniques. It is available in both single-sided and double-sided textured surfaces. BPM produces their HDPE textured geomembrane using high-quality imported HDPE raw materials and employs a professional production process and technology. The textured geomembrane liner is carefully packaged in double woven geotextile and a strength belt for added protection.

The rough surface of the HDPE textured geomembrane liner, whether on one side or both, significantly enhances the friction coefficient. This makes it particularly suitable for applications involving steep slopes and vertical engineering designs. The rough texture maximizes the effective volume of the geomembrane, providing increased frictional resistance. Furthermore, it retains the essential chemical and physical properties of a smooth HDPE geomembrane.

HDPE textured geomembrane liner offers unique features and benefits, including its textured surface, high-quality materials, and optimized production processes. It is designed to enhance friction and is well-suited for demanding applications in steep slopes and vertical engineering designs.

BPM high-density polyethylene textured geomembrane exhibits superior shear strength and the highest multi-axial performance which features superior high shear strength, big friction angles, outstanding elongation and highest interface surface friction coefficient. Our HDPE Textured geomembranes are widely applied for such projects which need increased friction between two layers and high steeper slopes as landfills, mining, oil & gas containment, retaining backfills and waste containment, etc.

BPM HDPE textured geomembrane is specially engineered as the chemical and fuel containment liner to contain oil drilling fluids and drill cuttings to prevent the water and soil from been polluted and contaminated by the oil or gas waste in the drilling and transportation processes. The textured geomembrane liner features high friction coefficient, good chemical resistance, UV resistance and good flexibility to resist tearing and puncture which are important factors should consider by the oil and gas industry.

2. Applications of Textured Geomembrane Liner for Oil and Gas Industry

Due to the multiple chemical components and slippery, viscous liquid status of petroleum outputs, HDPE textured geomembrane liner offers excellent anti-seepage containment solutions as followed.

- Drilling wastewater containment

- Oilfield pit liners

- Frac Pond Liners

- Rig Liner Systems

- Secondary containment & pad liners

- Evaporative and Brine Ponds

- Floating covers

- Tank liners

3. BPM Textured Geomembrane Liner for Chevron Petroleum Project

Introduced by Indonesia partner, BPM was certificated undertook the project of Chevron company to supply 120000 square meters HDPE textured geomembrane liner with thickness of 1.0mm. As soon as order confirmed, BPM started the production process, and BPM inspection department sending textured geomembrane samples cut from the production line to third party testing lab in Singapore as per client request.The delivered textured geomembrane sample was smoothly passed the test in accordance with GRI GM 13 by the third party testing lab test. The quality of BPM textured geomembrane liner was approved and praised by the Chevron Petroleum Engineers.

The signed order required 20 days to deliver the HDPE textured geomembrane liner products on site for the urgent construction of the oil and gas project. BPM production department took full use of the production line capacity to make sure the partial shipment of 3x40HQ container textured geomembrane and other left textured geomembrane rolls to arrive on time.

Chevron Corporation is one of the world’s leading integrated energy companies who works to meet the world’s growing demand for energy by exploring for oil and natural gas, refining and marketing gasoline, and Chevron’s operations spreaded all over the world. Chevron Corporation produces and transports crude oil and natural gas. BPM manufactured and supplied certificated HDPE textured geomembrane for subsidiary division in Indonesia. Due to the assured cases and big projects of HDPE geomembrane liner products in minging, oil & gas, landfill around the world, client was assured for BPM geomembrane quality.

When the textured geomembrane liner arrived onsite, BPM installation technicians joined the project team and stood there to guide the textured geomembrane installation with client workers. With more than 11 years installation experience, BPM technicians gave strict instructions and guidelines in the installation and welding processes for oil and gas lining system. BPM textured geomembrane liner provided a deep waterproofing lining system and its textured surface made the installation easier in slope area with its excellent friction coefficient.

Indonesia issued a wide range of environmental protection regulations and requirements in the oil and gas production processes.The finished lining project effectively provides protection functions in such sites as chemical plant, refinery, oil storage tank, etc. BPM textured geomembrane liner also played the economical role in the solid-liquid separation process for the large mount of mud and waste in the oil and gas drilling operations. The separated liquid phase is used for the preparation of drilling fluid recycling. By the formation of “recovery-adjustment-Reuse” treatment mode, solid wastes were centralized stacking, through the geomembrane lining system, and properly preserved.

The recycling and reuse of harmless treatment of substances such as slurry and wastewater are very important to decrease soil and water pollution in the oil and gas drilling process. The solid liquid separation of the drilling fluid is carried out by the advanced drilling fluid solid liquid equipment, the separated solids are recovered. The mud tank and the bottom of the tank are all installed with BPM HDPE tank liner and all lubricants and chemicals are stored in designated areas, covered with pads and clearly marked with textured geomembrane liner. Until now, BPM textured geomembrane liner has been running well to provide the strong protection for the Chevron Petroleum project.

About BPM

BPM have provided many types of effective and state of the art geomembrane, geotextile and geosynthetics products to over 36 countries. Our main innovative, high quality geosynthetics products include geomembrane, geotextiles, geocell, geosynthetic clay liners (GCLs), drainage boards, geogrids, etc. BPM brand PET geosynthetics had been certificated by the ISO9001, ISO14001,OHSAS18001 Soncap, SASO and BV certificates and passed the test of SGS and Intertek, etc.

BPM is also providing professional design and installation service. OEM and ODM are also available. If you have any questions or inquiries, please contact us, we will reply as soon as possible.