The application of geosynthetics in civil engineering is becoming more and more recognized nowadays because of its special advantages. Geosynthetics have proven to be among the most versatile and cost-effective ground modification materials. Their usages have expanded rapidly into nearly all areas of civil, geotechnical, environmental, coastal, and hydraulic engineering. As the leading geosynthetics manufacturers, wholesalers and suppliers, The Best Project Material Co., Ltd (BPM) had been dedicated to supplying one stop geosynthetics products and services to worldwide customers since its foundation in 2007. We have over 120 professional staffs and 16,000 square meters manufacturing factory equipped with state of the art production lines. All BPM brand geosynthetic prodcuts had been certificated by the ISO9001, ISO14001, Soncap, SASO and BV certificates and passed the test of SGS and Intertek etc. The application of geosynthetics spreads across the functions of separator, filter, planar drain, reinforcement, protection, and as a liquid or gas barrier. The various types of appliaction of geosynthetics is available along with their specific features.

The advantages of the application of geosynthetics in civil engineering

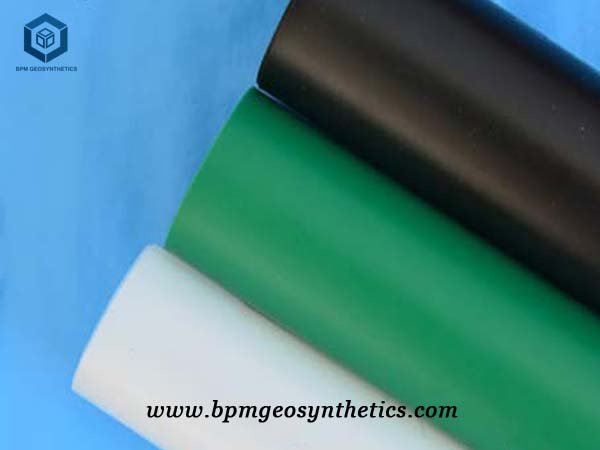

Geosynthetics, including geotextiles, geomembranes, geonets, geogrids, geocomposites and geosynthetic clay liners, are often used in combination with conventional materials which can offer the following advantages over traditional materials.

- Space Savings. Sheet-like, geosynthetics take up much less space in a landfill than do comparable soil and aggregate layers.

- Material Quality Control. Geosynthetics are relatively homogeneous because they are manufactured under tightly controlled conditions in a factory. They undergo rigorous quality control to minimize material variation.

- Construction Quality Control. Geosynthetics are manufactured and often factory “prefabricated” into large sheets. This minimizes the required number of field connections, or seams. Both factory and field seam are made and tested by trained technicians.

- Cost Savings. Geosynthetic materials are generally less costly to purchase, transport and install than soils and aggregates.

- Technical Superiority. Geosynthetics have been engineered for optimal performance in the desired application.

- Construction Timing. Geosynthetics can be installed quickly, providing the flexibility to construct during short construction seasons, breaks in inclement weather, or without the need to demobilize and remobilize the earthwork contractor.

- Material Availability. Numerous suppliers of most geosynthetics and ease of shipping insure competitive pricing and ready availability of materials.

- Environmental Sensitivity. Geosynthetic systems reduce the use of natural resources and the environmental damage associated quarrying, trucking, and other material handling activities.

The Application of Geosynthetics in Civil Engineering

The functions of the geosynthetics, in conjunction with the advantages they offer, have made them suitable for a wide range of applications and have caused them to be vastly used in many, if not all, areas of infrastructure development. The application of geosynthetics has been spread in many civil, geotechnical, transportation, geoenvironmental, hydraulic and private development applications including roads, airfields, embankments, retaining structures, reservoirs, canals, dams, erosion control, sediment control, landfill liners, landfill covers, mining, aquaculture and agriculture.

Within each of the areas mentioned above, the appliction of geosynthetics is found in many areas. It will be almost impossible to mention all the areas of application of geosynthetics in infrastructure development, since these are areas run into hundreds in number. However, a few of these areas of application of geosynthetics in infrastructure development will be mentioned here.

- Geosynthetics in Transportation Engineering

Geogrids have been used for soil reinforcements in embankments and walls, subgrade stabilization, and embankment base reinforcement. Geogrids are characterized by integrally connected elements with in-plane apertures uniformly distributed between the elements. The apertures allow the soil to fill the space between the elements, thereby increasing soil interaction with the geogrid and ensuring unrestricted vertical drainage. All these applications are not only in highway, but also in railroad track construction and rehabilitation. - Geosynthetics in Drains

Geomembranes have been successfully used as the waterproofing element in embankment dams, to rehabilitate old concrete and masonry dams in order to reduce leakage phenomena that typically appear on these structures after 30 to 40 years of operation, depending on the accuracy of construction and on conditions of the damsite. Geosynthetics have also been used as chimney drains, filters between fine-grained cores and shells of earthfill and rockfiil dams, as drains, as filters between the foundation of the dam for stability, as protection for the upstream slope facings of the dams, and as erosion control features on the downstream slope facings. - Geosynthetics in Coastal defence installations

Geosynthetics have also found application in coastal defence installations. Geosynthetic technologies have emerged as a major tool in the battle against shoreline erosion. Geotube system involves filling a very large tubular textile containers with local sand and sludge to hold unstable banks in place. Shoreline stabilization frequently is accomplished with membranes covered by concrete or stone’ geotube eliminate the need to transport those materials. - Geosynthetics in Earth Retention and Slope Stability

Geocells have been employed to protect slopes against erosion, stabilize steep slope surfaces, provide protective linings for channels, support heavy construction traffic on the weak subgrade soils, and provide multi-layered earth-retaining structures. Geocells are typically constructed of high-density polyethylene. The cells in the three-dimensional panels are opened and filled with granular material, which adds weight to make the multi-layer system act as a gravity retaining wall. - Geogrids are also mainly used for reinforcement applications such as reinforced vertical walls and steep slopes as well as reinforced foundations.

Geotextiles can improve soil strength at a lower cost than conventional soil nailing. In addition, geotextiles allow planting on steep slopes, further securing the slope. - Geosynthetics in Landfills

Geomembranes serve as hydraulic barriers and have been used in conjunction with geonets in landfill applications. They have also been used for containment of spills, leaking underground storage tanks, or hazardous materials.

Geopipes are used for drainage of liquids or gas. In some cases, the perforated pipe is wrapped with a geotextile filter. - Geosynthetics in Water and Liquid Containment Applications

Geomembranes, as well as geosynthetic clay liners, are relatively impermeable and are used as liners for fluid or gas containment. They are used in the area of potable wastewater treatment, golf and decorative ponds, aquaculture ponds, floating covers, etc. - Geosynthetics in Drainage Systems

Geocomposites are designed to replace aggregate and or perforated pipe subsurface drainage systems. Geocomposite consists of a deformed, perforated, or slotted plastic core and a geotextile (filter) fabric wrap. Geocomposites include geonets, pavement edge drains, and sheet drains. - Geosynthetics in Erosion and Sediment Control

Geosynthetics have been placed in drainage channels to collect storm water, while geonets have been used to line these same channels to permit the growth of vegetation through them whereby the erosion of the drainage channel is curtailed. Geosynthetics have also been used for sediment control.

About BPM

BPM had provided many types of effective and state of the art geosythetics products to over 36 countries. Our main innovative, high quality geosynthetics products include geomembranes, geotextiles, geocells, geosynthetic clay liners (GCLs), drainage boards, geogrids, etc. BPM brand HDPE geosynthetics had been certificated by the ISO9001, ISO14001,OHSAS18001 Soncap, SASO and BV certificates and passed the test of SGS and Intertek etc. Our main customers are from Australia, France, Sweden, UK, Hong Kong, Hungary, New Zealand, Poland, Mexico, Ecuador, Brazil, Pakistan, Bangladesh, Thailand, Vietnam, Malaysia, Indonesia, Singapore, Philippines, Sri Lanka, India, UAE, Saudi Arabia, Qatar, Kenya, Ghana, Ethiopia, Somalia, Nigeria, South Africa, Swaziland, Mongolia etc.

BPM is not only manufacturing best quality geosynthetics, geomembrane, geotextile products but also providing professional design and installation service. OEM and ODM are also available. If you have any questions or inquiries, please fill and submit the following form, we will reply as soon as possible.