Reinforced Polyethylene Pond Liner provides an affordable and durable solution for a variety of water containment applications. It is suitable for applications where strength, tear resistance, and long life are required. Their versatility and reliability make them a popular choice for a variety of pond and water management projects in various industries and fields. Over the past decade, Geomembrane Pond Liner has played an important role in geotechnical engineering. Our BPM GEOSYNTHETICS geomembranes have been installed in various engineering projects around the world. With 20 years of geotechnical engineering experience, we provide our customers with quality Reinforced Polyethylene Pond Liner products and professional geomembrane installation experience. Next, this article will start from the definition, advantages, and application of RPE membrane in various projects.

1. What Is Reinforced Polyethylene Pond Liner?

Reinforced Polyethylene Pond Liner is a type of liner material that is specifically designed to provide enhanced durability and strength for pond construction. It is made from high-quality polyethylene, which is known for its excellent resistance to chemicals, UV rays, and punctures. This makes it an ideal choice for lining ponds, as it can effectively prevent water leakage and protect the pond from environmental factors.

One of the leading manufacturers in this field is BPM Geosynthetics. They specialize in producing a wide range of geosynthetic materials, including reinforced polyethylene pond liners. Their products are known for their superior quality and performance, making them a trusted choice among pond builders and environmental engineers. With BPM Geosynthetics’ reinforced polyethylene pond liners, you can be assured of a reliable and long-lasting solution for your pond lining needs.

2. Advantages of Reinforced Polyethylene Pond Liner

Reinforced polyethylene pond liners excel in resisting punctures, tears, and dimensional changes. They guarantee long-term performance and dependably prevent leaks. Moreover, these liners withstand UV radiation, chemicals, and environmental stresses, adapting to various climates and water conditions with ease.

2.1 Reinforced Polyethylene Pond Liner – Enhanced strength

The reinforcement layer in the pond liner, therefore, plays a crucial role in enhancing its overall strength. Consequently, this added robustness makes the liner more resistant to tearing and punctures. As a result, the improved strength guarantees a significantly longer lifespan for the liner.

2.2 Reinforced Polyethylene Pond Liner – Enhanced durability

The additional reinforcement layer, therefore, boosts the durability of the polyethylene pond liner. Consequently, this enhancement enables the liner to better withstand harsh environmental conditions and daily wear and tear. As a result, the liner can maintain its integrity and functionality over an extended period.

2.3 Reinforced Polyethylene Pond Liner – Improve tear resistance

Reinforcements in the liner, therefore, offer enhanced tear resistance. Consequently, this feature reduces the probability of accidental damage. As a result, the liner can retain its integrity for a longer duration.

2.4 Reinforced Polyethylene Pond Liner – Better puncture resistance

Reinforced polyethylene pond liners, therefore, provide superior puncture resistance. Consequently, this quality makes them more resilient and capable of withstanding sharp objects or debris. As a result, the liner remains well-protected against potential damage.

2.5 Reinforced Polyethylene Pond Liner – Stability and structural integrity

The reinforcement layer, therefore, plays a crucialThe reinforcement layer, therefore, plays a crucial and structural integrity of the pond plays a crucial role in enhancing the stability and structural integrity of the pond liner. Consequently, this improvement ensures that the liner maintains its shape and contains water effectively. As a result, the liner is better equipped to resist deformation and perform its intended function over time.

2.6 Reinforced Polyethylene Pond Liner – Versatility

Reinforced Polyethylene Pond Liners are, therefore, extremely versatile and can be utilized in a wide range of applications. Consequently, they are suitable for large ponds, aquaculture, wastewater treatment ponds, decorative ponds, and even industrial settings. As a result, these liners offer a flexible solution for diverse containment needs.

2.7 Reinforced Polyethylene Pond Liner – Affordable

Although the initial cost is higher than standard polyethylene liners, enhanced polyethylene pond liners, therefore, offer significant long-term cost savings. Consequently, their extended lifespan and reduced maintenance requirements result in lower overall expenses over time. As a result, these liners provide a more economical choice in the long run.

2.8 Reinforced Polyethylene Pond Liner – Reliable accommodation

Reinforced Polyethylene Pond Liners, therefore, offer a dependable containment solution. Consequently, they effectively prevent leaks and seepage that could otherwise lead to environmental pollution. As a result, these liners play a crucial role in safeguarding ecosystems and preventing contamination.

2.9 Easy installation

Despite its extra strength, reinforced polyethyleneDespite its extra strength, reinforced polyethylene therefore, relatively easy to install Consequently, this feature saves both time and labor costs during the construction process. As a result, the installation becomes more efficient and cost-effective.

2.10 Environmental friendly

Polyethylene is, therefore, a recyclable material. Consequently, this makes reinforced polyethylene pond liners an environmentally friendly choice for water containment applications. As a result, these liners contribute to sustainable practices and reduced environmental impact.

3. Application Of Reinforced Polyethylene Pond Liner

Reinforced Polyethylene Pond Liners are widely used in a variety of applications, their strength, durability and stability make them ideal for water containment projects, whether in agriculture, industry or municipal fields.

- Large ponds and lakes:Reinforced Polyethylene Pond Liners are often used in the construction of large ponds and lakes where a strong liner is needed to withstand water pressure and environmental factors.

- Aquaculture and fisheries:Suitable for use in aquaculture and fishery applications, these liners provide a reliable barrier for containing water and aquatic life.

- Wastewater treatment pool:Reinforced Polyethylene Pond Liners are used in wastewater treatment ponds to prevent leakage and contamination of the surrounding soil and groundwater.

- Decorative ponds and water features:They are also used in decorative ponds, water features and gardening projects to create water features that require a strong and durable lining.

- Industrial Applications:Reinforced Polyethylene Pond Liners are used in various industrial settings for containment purposes, such as storing chemicals, liquids or industrial wastewater.

- Agricultural reservoir:Farmers use these liners in agricultural reservoirs and irrigation ponds to store water for crop irrigation and livestock drinking..

- Stormwater Management:In stormwater management systems, reinforced polyethylene pond liners are used to create detention ponds that help control stormwater runoff and prevent flooding.

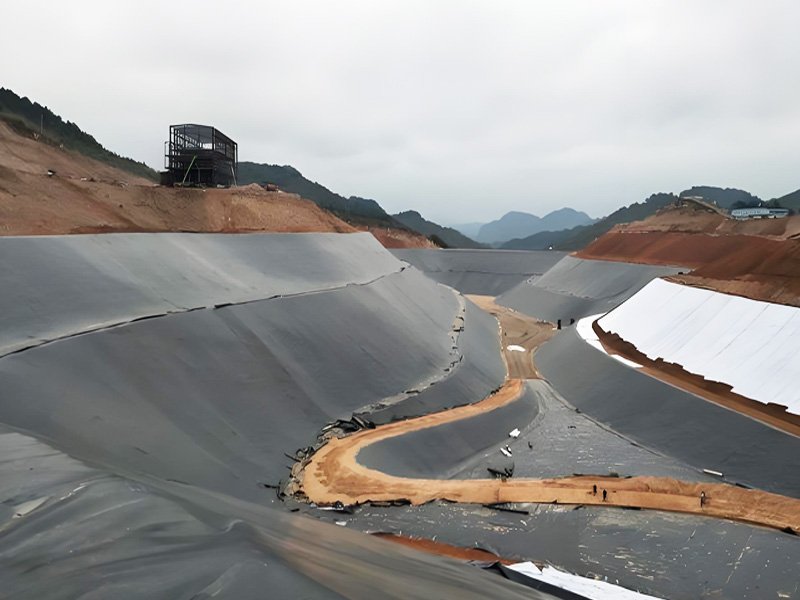

- Mining and landfill applications:They are used in mining operations and landfills to contain liquids, leachates or waste materials, providing environmental protection and containment.

4. How To Properly Install Reinforced Polyethylene Pond Liner?

Installing a reinforced polyethylene pond liner is a critical step in ensuring the longevity and effectiveness of your pond or water containment system.

4.1 Site Preparation

Before installing the liner, it’s essential to prepare the site properly. Start by clearing the area of any debris, rocks, or sharp objects that could potentially damage the liner. Level the ground as much as possible to avoid uneven stress on the liner, which could lead to premature failure.

4.2 Measuring and Cutting the Liner

Carefully measure the dimensions of your pond or containment area. It’s crucial to get these measurements right the first time to minimize waste and ensure a perfect fit. Lay out the liner material and mark the cuts, allowing for a small overlap (usually about 12-18 inches) around the edges for anchoring and seam allowance.

4.3 Unrolling and Positioning the Liner

Unroll the liner carefully, starting from one end and working your way across the pond. Avoid dragging the liner over rough surfaces to prevent tears or punctures. Position the liner so that it extends slightly beyond the edges of the pond, leaving enough material for anchoring and seaming.

4.4 Smoothing Out Wrinkles

Once the liner is in place, walk over it to smooth out any wrinkles or air pockets. This step is vital as wrinkles can collect water and lead to premature wear or even failure of the liner. Use a soft broom or your hands to gently smooth the liner, working from the center towards the edges.

4.5 Trimming Excess Material

After the liner is smooth and well-positioned, trim any excess material from the edges, leaving about 12-18 inches for anchoring. Be sure to cut the material straight and cleanly to ensure a proper seal during the anchoring process.

4.6 Anchoring the Liner

Anchor the liner along the perimeter of the pond using suitable anchoring methods, such as sandbags, soil backfill, or concrete anchors. This step is crucial to keep the liner in place and prevent movement that could cause damage or failure.

4.7 Seaming the Seams

If multiple sheets of liner are used or if there are any seams, use a hot air welding technique or an appropriate adhesive to seam the joints together. Ensure that the seams are strong and watertight to prevent leaks.

4.8 Quality Check and Backfilling

After installation, conduct a thorough quality check to ensure there are no leaks or weak points. Once satisfied, backfill around the edges with soil or another suitable material to provide additional support and stability.

By following these steps, you can ensure a proper installation of a reinforced polyethylene pond liner, providing a durable and effective solution for your water containment needs.

5. Summary

In summary, reinforced polyethylene pond liners represent a significant advancement in geosynthetic solutions, offering unparalleled durability, adaptability, and environmental sustainability. These specialized liners, enhanced with reinforcing materials for added strength and resilience, have transformed the landscape of water containment and management systems across various industries.

BPM Geosynthetics stands at the forefront of this innovation, boasting state-of-the-art production lines that ensure the highest quality standards are met consistently. With a focus on delivering superior performance without compromising on affordability, BPM Geosynthetics offers a product range that is synonymous with high quality and exceptional value for money. Customers can trust in our expertise and advanced manufacturing processes to provide them with liners that promise longevity, minimal maintenance, and optimal performance in their water containment projects. Choose BPM Geosynthetics for your next project, where quality meets cost-effectiveness without compromise.