Description

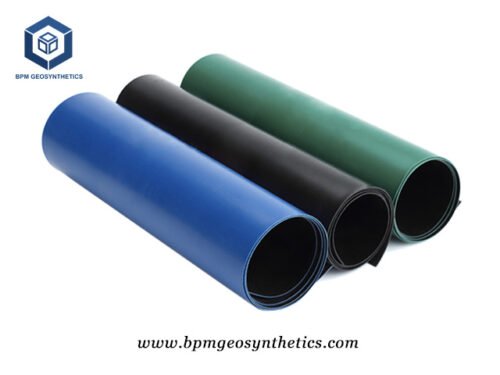

Textured HDPE Geommebrane, also knwon as textured geomembrana, is designed and fabricated with either single-sided or double-sided textured surface improve friction between two layers. As the leading HDPE geomembrane manufacturer and supplier, BPM Geosynthetics offers high quality custom HDPE textured geoembrane with complete size, thickness and specifications at competitive factory price.

1. What Is Textured HDPE Geoemembrane?

Textured HDPE geomembranes are a type of liner widely used in environmental and civil engineering applications. Geomembranes are impermeable barriers made of synthetic materials, typically polymeric, that regulate fluid movement in geotechnical and environmental projects.

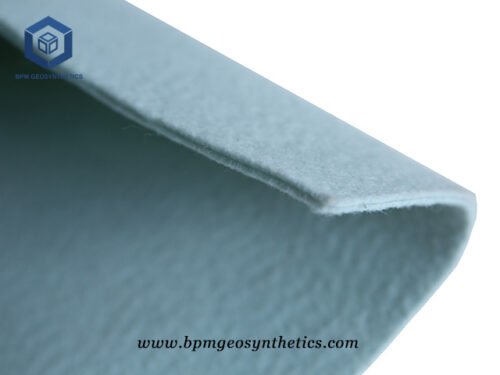

Textured HDPE geomembrane liners offer several beneficial properties. They exhibit excellent temperature adaptability, weldability, weather resistance, aging resistance, chemical resistance, environmental stress crack resistance, and puncture resistance. These liners are specifically designed to prevent seepage and are considered a new and effective anti-seepage material.

HDPE geomembrane liners with a textured surface provide additional advantages. They increase the friction coefficient and possess anti-skid functionality, making them particularly suitable for applications on steep slopes and vertical surfaces where preventing seepage is critical. The textured surface enhances engineering stability and ensures reliable performance

Textured HDPE Geomembrane has a rough surface which can highly improve the friction coefficient which fits more suitable for steep slope and vertical engineering design work which maximize the effective volume of geomembrane, they are also processed with smooth edges to allow for high quality thermal fusion welding between adjacent sheets.

Textured geomembranes, specifically textured HDPE geomembranes, are impermeable membranes used in various geotechnical engineering projects. These membranes, made from high-density polyethylene blended with carbon black, anti-aging agents, UV absorbers, and stabilizers, are extensively used in sewage pond facilities. BPM Brand offers a high-density textured geomembrane that is cost-effective, chemically resistant, and easily deployable. It withstands exposed conditions and facilitates convenient transportation. The textured HDPE geomembrane from BPM showcases impermeability, high tensile strength, exceptional chemical resistance, and outstanding stress crack capacity. These features make it an ideal choice for sewage containment, ensuring superior performance and reliability.

2. Textured HDPE Geomembrane Specifications

| Test Properties | Unit | Standard | Test frequency | BM10 | BM15 | BM20 | BM25 |

|---|

| Thickness | mm | D5994 | per roll | 1.00 | 1.50 | 2.00 | 2.50 |

| Asperity Height | mm | D7446 | Every 2nd roll (2) | 0.25 |

| Density | g/cc | D1505/D792 | 90,000kg | 0.94 |

| Tensile Properties |

| Yield Strength | KN/m | D6693 Type IV | 9,000 kg | 15 | 22 | 29 | 37 |

| Break Strength | KN/m | 10 | 16 | 21 | 26 |

| Yield Elongation | % | 12 | 12 | 12 | 12 |

| Break Elongation | % | 100 | 100 | 100 | 100 |

| Tear Resistance | N | D1004 | 20,000kg | 125 | 187 | 249 | 311 |

| Puncture Resistance | N | D4883 | 20,000kg | 267 | 400 | 534 | 667 |

| Stress Crack Resistance | hr | D5397(App) | per GRI GM-10 | 300 hr |

| Carbon black content | % | D4218 | 9,000kg | 2.0-3.0% |

| Carbon black dispersion | | D5596 | 20,000kg | For 10 different views: 9 in Categories 1 or 2 and 1 in Category 3 |

| Oxidative Induction Time |

| Standard OIT | min | D3895 | 90,000kg | 100 min |

| High pressure OIT | D5885 | 90,000kg | 400 min |

| Oven Aging at 85°C retained after 90 days | % | D5721 | per each formulation | 55% |

| Standard OIT | | D3895 | 80% |

| High pressure OIT | | D5885 | 80% |

| UV Resistance |

| High Pressure OIT – % retained after 1600 hrs | % | D5885 | per each formulation | 50% |

| Roll Width | m | | | 7 | 7 | 7 | 7 |

| Roll Length | m | | | 210 | 140 | 105 | 70 |

| Size stability | % | | | 2% |

3. What Are Types Of Textured Geomembrane?

Textured geomembranes are specifically designed with surface patterns or textures to enhance their frictional characteristics and provide better interface friction with soils or other materials. There are four types of textured geomembranes including single-sided, double-sided, micro-textured and macro-textured sureface geomembrane.

Single-sided textured geomembrane has one textured side and one smooth side. In slope anti-seepage engineering, the textured side is often placed in contact with geotextiles to increase frictional resistance and stability, preventing slippage.

Double-sided textured geomembrane features textured surfaces on both sides. This provides enhanced frictional properties and is beneficial when interaction with the substrate is important on both sides of the geomembrane.

Micro-textured geomembranes have subtle surface textures that improve interface friction while maintaining a smooth appearance.

Macro-textured geomembranes, on the other hand, have larger and more pronounced surface textures. They are used in applications where a higher level of frictional resistance is required.

4. What Are The Advantages of Textured HDPE Geomembrane?

BPM Textured HDPE geomembranes offer several advantages:

- Geomembranes with Superior Single- or Double-sided Textured Surface.

- Superior flexibility and elongation.

- Long performance and durability.

- Enhanced frictional coefficient, making them suitable for applications on steep slopes. This helps prevent soil erosion and provides stability in challenging terrain.

- Ultraviolet and chemical resistance caused by UV exposure and other environmental factors, maintaining their integrity and performance.

- Excellent UV environmental stress crack resistance.

- High tensile strength and low elongation.

- Excellent corrosion and aging resistance .

- Impermeable, antifouling, antiskid function.

- Easy to install and work with, facilitating efficient and cost-effective construction processes.

- Meets or exceeds all requirements set by the Geosynthetic Research Institute’s GRI GM13 standard, ensuring high quality and performance.

- Cost effective, Factory price.

- Careful robust package.

- ODM/OEM are available.

5. How Do Textured Geomembranes Enhance the Slope Stability?

Textured geomembranes enhance slope stability through increased friction, improved interface bonding, reduced sliding potential, enhanced load distribution, and improved seepage control. The textured surface provides a higher friction coefficient, promotes better bonding with adjacent materials, acts as a barrier against sliding, distributes loads evenly, and enhances seepage resistance. These features collectively improve the stability of geomembranes in slope applications, reducing the risk of movement, slippage, and liner failure.

6. What Are Textured Geomembrane Used For?

Textured geomembranes have wide applications in environmental and civil engineering projects, including slope anti-skid and seepage prevention, landfill liners, tailings ponds, environmental containment systems, water and wastewater treatment facilities, and mining and industrial applications. These geomembranes with their textured surface provide increased frictional resistance and stability, making them suitable for slope protection and erosion prevention. They are used as liners in landfills to prevent contamination, in tailings ponds for waste management, and in various containment systems to ensure fluid containment. Textured geomembranes also find use in water and wastewater treatment facilities, as well as in mining and industrial settings, providing reliable seepage control and environmental protection. With their specialized features, these geomembranes play a vital role in the success and sustainability of engineering projects.

7. About BPM

BPM had been specializing in delivering one stop geosynthetics products and solutions to worldwide customers since its foundation in 2007. BPM had provided many types of effective and state of the art geomembranes, geotextiles, geocells, geosynthetic clay liners (GCLs), drainage boards, geogrids to over 36 countries. Our main customers are from Australia, France, Sweden, UK, Hong Kong, Hungary, New Zealand, Poland, Mexico, Ecuador, Brazil, Pakistan, Bangladesh, Thailand, Vietnam, Malaysia, Indonesia, Singapore, Philippines, Sri Lanka, India, UAE, Saudi Arabia, Qatar, Kenya, Ghana, Ethiopia, Somalia, Nigeria, South Africa, Swaziland, Mongolia etc.

BPM is not only manufacturing best quality geomembrane and geosynthetic products but also providing professional design and installation service. OEM, ODM, custom development and fabrication are also available. If you have any questions or inquiries, please fill and submit the following form, we will reply as soon as possible.