HDPE reinforced polyethylene liner has very good UV resistance and functions even in cold temperatures. It has also high tensile strength, it is not prone to sudden length-wise tears. The reinforced polyethylene liner has most desirable characteristics, it also might be superior resistance to a wide range of chemicals. The HDPE reinforced polyethylene liner has relatively inexpensive price, multiple geomembrane liner can be joined using HDPE liner welding machine. HDPE geomembrane liners are commonly used in landfills and chemical containment sites, but they are also safe and well-suited for fish ponds. No matter where they are, HDPE reinforced polyethylene liner is very durable, is can be last up to 36 years when covered. Followed are the typical characteristics of HDPE reinforced polyethylene liner.

- Excellent chemical resistance

- Good UV resistance

- Relatively inexpensive

- Weldable

- Very durable

- 36+-year lifespan when covered

- Performs well in cold temperatures

BPM high density polyethylene pond liner is manufactured by high quality Polyethylene virgin raw material , adding carbon black, antioxidant, anti-aging and UV resistance component. BPM have the first class automatic blowing film production liner and flat die production line.

Oxidation pond is a general term for structures that use natural purification capacity to treat sewage. The purification process is similar to the self-purification process of natural water bodies. Usually, the land is properly trimmed, a pond is built, and a dike and an impermeable layer are set up, and the sewage is treated by the microorganisms growing in the pond. The oxidation pond mainly uses the combined action of bacteria and algae to treat organic pollutants in wastewater. The sewage treatment system of the oxidation pond has the advantages of low capital investment and operating costs, simple maintenance and repair, easy operation, effective removal of organic matter and pathogens in the sewage, and no need for sludge treatment. Due to the excellent acid and alkali resistance of high density polyethylene pond liner and the stability of chemical reactions, it is widely used in large-scale projects such as oxidation ponds, biogas ponds, sedimentation ponds, oil and gas, landfills, salt plants, etc.

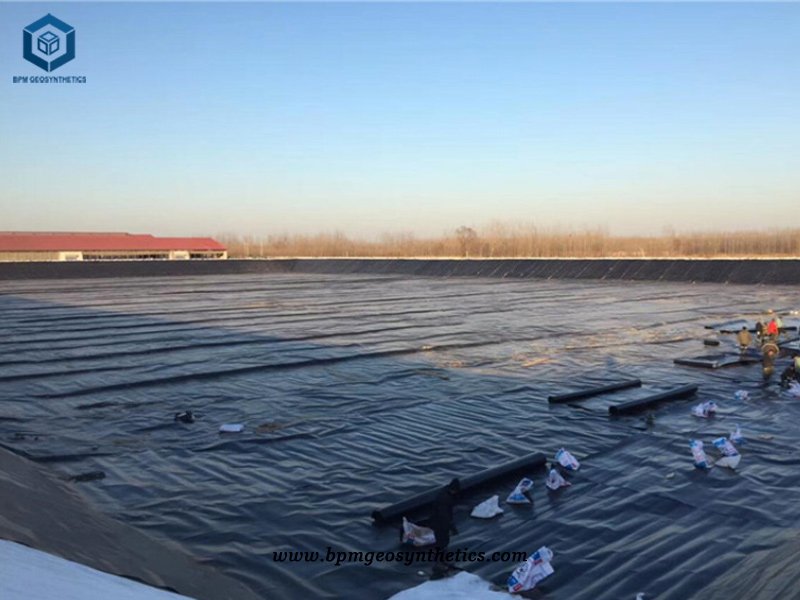

BPM customers found us on our website and exchange ideas about his oxidation pond with us. After telephone communication, we decided to visit the customer’s local area and communicated with the customer face to face. After arriving at the location, our engineers learned about the local situation and exchanged their ideas with customers in a simple way. In addition to the construction of the oxidation tank, a series of tanks including sedimentation tanks and biogas tanks should be built. In the early days, we first designed the oxidation tank plan for the customer. We suggested using 1.5mm geomembrane pond liner, laying 400gsm geotextile fabric at the bottom of HDPE geomembrane layer, and HDPE pipes is designed for drainage. We measured all the dimensions on the spot and calculated the required quantity. At the beginning, we first designed two solutions for the customer. One was that we only provide HDPE reinforced polyethylene liner and short fiber geotextile fabric materials and the customer, the customer carried out the construction. The other is that we installed and constructed for the customer. Because the customer had little experiences in the geomembrane liner and geotextile installation, they chose our second plan and handed over all the projects to us for construction. We expected a construction period of about ten days, but during the period it was rainy and it was delayed by two days.

Because the groundwater level was relatively low, we laid a layer of pipes before laying geotextile and geomembrane. The purpose is to prevent groundwater from rising in the future, causing the bottom of the geomembrane pond liner to expand and affecting the normal operation of the oxidation pond. We have drilled a small hole in each HDPE pipe, and let water drop into the pipe along the small hole and then drain out. We chose HDPE tube because it is more expensive and its service life is relatively long. We have laid a total of two rows of HDPE pipes, each of which had more than a dozen holes, which greatly increased the efficiency of drainage. After the pipeline was laid, we laid a pebble on the pipe. The pebble also assisted in dredging the water.

After the pipeline is laid, the ground must be leveled, and then the shor fiber non woven geotextile fabric sould be be laid. Geotextile was a permeable geosynthetic material made of synthetic fibers through needle punching or weaving. It has the functions of filtration, drainage, isolation, reinforcement and maintenance. Its characteristics are as followed

- High strength. Due to the use of plastic fibers, it can maintain sufficient strength and elongation in dry and wet conditions.

- Corrosion resistance, long-term corrosion resistance in soil and water with different pH levels.

- Good water permeability. There are gaps between the fibers, so it has good water permeability.

- Good anti-microbial properties, no damage to microorganisms and insects.

- Convenient construction. Because the material is light and soft, it is convenient to transport, lay and construct.

Laying a layer of needle punched geotextile fabric under the geomembrane reinforced polyethylene liner can not only play a filtering role, but also can protect the geomembrane pond liner from being pierced by sharp objects. We chose 400gsm staple fiber needle punched geotextile, which can not only filter water well, but also protect the HDPE geomembrane liner. We installed a layer of geotextile fabric at the bottom first, and then laid the geomembrane reinforced polyethylene liner, so as to protect the geotextile fabric from pollution. The laying process is relatively quickly due to our years experiences in this field.

We recommended the thickness of 1.5mm thickness geomembrane reinforced polyethylene liner with the o our customers, because the 1.5mm geomembrane is thicker, its stability will be better and it will better waterproof functions. The customer needed a total of 23,000 square meters geomembrane pond liner.

After the geomembrane was laid, it needed to be welded with a HDPE Liner welding machine. We used the BPM900 HDPE liner welding machine for the 1.5mm geomembrane pond liner which can weld about 8,000 square meters per day. When welding the geomembrane liner, try your best to keep the geomembrane clean, otherwise the welding process will have defects and the waterproof effect will not be good. After more than ten days of construction, the welding of the oxidation pond was finally completed, and the customer was very satisfied with the project we did.

About BPM

BPM has been specializing in delivering one stop geosynthetics products and solutions to worldwide customers since its foundation in 2007. BPM had provided many types of effective and state of the art geomembranes, geotextiles, geocells, geosynthetic clay liners (GCLs), drainage boards, geogrids to over 81 countries. Our main customers are from Australia, France, Sweden, UK, Hong Kong, Hungary, New Zealand, Poland, Mexico, Ecuador, Brazil, Pakistan, Bangladesh, Thailand, Vietnam, Malaysia, Indonesia, Singapore, Philippines, Sri Lanka, India, UAE, Saudi Arabia, Qatar, Kenya, Ghana, Ethiopia, Somalia, Nigeria, South Africa, Swaziland, Mongolia etc.