60 mil HDPE liner, also known as 60 mil high density polyethylene liner,is the kind of most widely used geomembrane in the world and is used more commonly internationally due to its availability and relatively inexpensive material cost. BPM smooth geomembrane HDPE liner is made of raw material, adding carbon black, antioxidant, anti-aging and UV-resistance component by the state of the art automatic production lines and advanced pressing technology. It has features of excellent chemical resistance, outstanding stress crack capacity, lowest permeability and excellent UV resistance, etc. 60 mil HDPE liner is an excellent product for large applications that require UV and Ozone resistance, chemical resistance or high-quality installations. Geomembrane HDPE liner is widely used across a variety of industries including waste, water, aquaculture, mining, power plant, industrial and civil engineering, etc.

With the economic development, the demand for mineral products has increased significantly, the scale of mining development has increased, and the amount of mineral tailing produced will continue to increase. The large amount of tailing piled up will cause many problems for the mining, environment and economy, the tailing composition and the residual dressing agent has seriously damaged the ecological environment, especially the heavy metal-containing tailing, in which sulfide produces acidic water to further leach heavy metals, and the loss will cause harm to the entire ecological environment. HDPE geomembrane liner, especially the 60 mil HDPE liner, is the ideal geotechnical material to deal with the mineral tailings to protect the environment. 60 mil HDPE liner is a waterproof barrier type material that uses high molecular polymer as the basic raw material. The main mechanism is to block the water leakage channel of the earth dam with the impermeability of the plastic film, with its greater tensile strength and elongation to withstand the water pressure and adapt to the deformation of the dam body.

1. What Is the Thickness of a 60 mil HDPE Liner?

A mil represents one-thousandth of an inch, equivalent to 0.001 inches or 0.0254 millimeters. It’s crucial to note that a mil is distinct from a millimeter and serves as a unit of measurement rather than an abbreviation.

HDPE liner thickness for anti-seepage applications typically ranges from 0.5mm to 3.0mm, with options like 0.75mm, 1.0mm, 1.25mm, 1.5mm, 2.0mm, 2.5mm, 3.0mm, and 3.5mm. For instance, a 20-mil pond liner is 0.02 inches thick, while a 60 mil HDPE liner is 0.06 inches thick.

In mining projects, the most common thickness is 60 mil (1.5 mm). This thickness enhances physical strength, reduces permeability compared to a 40 mil HDPE liner, and improves weathering resistance for exposed applications.

It’s crucial to ensure that the minimum thickness of 60 mil textured HDPE is not less than 54 mils (0.054 inches) in 8 out of 10 measurements across the roll width, considering a specification thickness of 0.060 inches with a 10% tolerance.

BPM 60 mil HDPE liner is a durable, non-biodegradable and waterproof plastic that is available in a variety of thicknesses in 100′ lengths. It can be used in hot and cold climates and is rodent and insect resistant. This HDPE geomembrane liner has a 50 year lifespan when installed under ground and not in direct sunlight. This mildew and rot resistant plastic roll can be installed vertically or horizontally and is tear and puncture resistant. It can be used in hot and cold climates and is also rodent and insect resistant.

The 60 Mil HDPE Liner is made by China HDPE liner manufacturer and is smooth geomembrane liner that is easy to install and is available in width options ranging from 18″ to 60″.

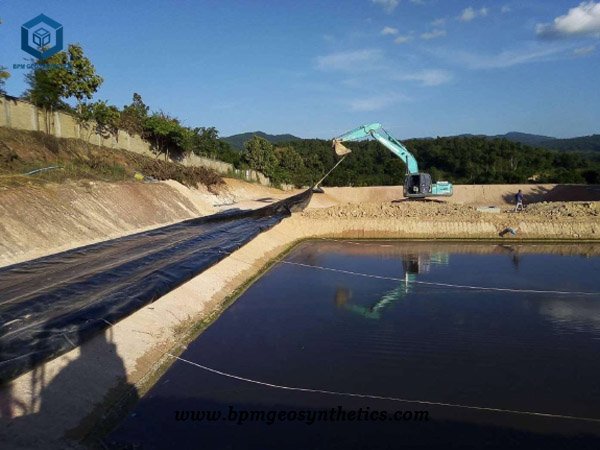

Our client from Kenya oversees HDPE geomembrane liner playing a significant role in a mining project, and BPM geomembrane had the opportunity to collaborate with them. During the interaction, we presented comprehensive information about the specifications and diverse applications of our 60 mil HDPE liner products. Additionally, we offered valuable insights and guidance on the installation process. The client expressed contentment with our professional advice, recognizing the expertise we brought to the table. This positive exchange swiftly paved the way for a collaborative partnership between BPM and the client, emphasizing the satisfaction derived from our product knowledge and supportive guidance throughout the consultation process.

3. Specifications of 1.5 mm HDPE Geomembrane Liner for Mining Project in Indonesia

- Total HDPE liner quantity – 23,100 square meters

- Each roll size – 7m*140m

- HDPE Liner Thickness – 60 mil or 1.5 mm

4. About BPM Geosynthetics

BPM has been specializing in delivering one stop geosynthetics products and solutions to worldwide customers since its foundation in 2007. BPM had provided many types of effective and state of the art geomembranes, geotextiles, geocells, geosynthetic clay liners (GCLs), drainage boards, geogrids to over 81 countries.

f you have any questions or inquiries, please contact us.