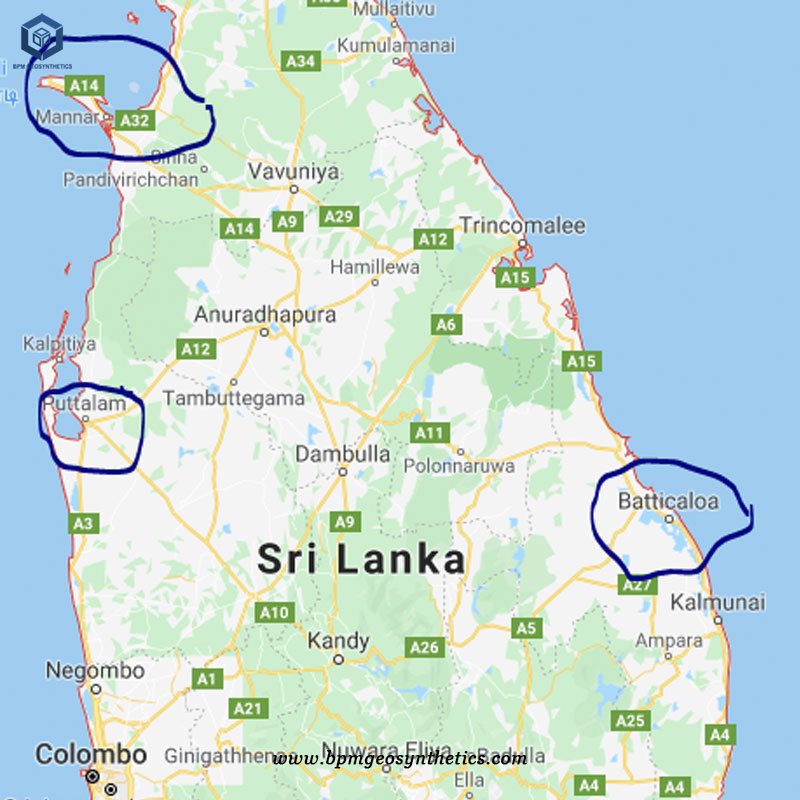

Geomembrana HDPE liner, also known as HDPE geomembrane liner, is the ideal geosynthetic material for anti seepage lining projects such as aquaculture farm, water containment, waste containment and landfill applications. BPM Geosynthetics had provided more than 300,000 square meters geomembrana HDPE liner, 20 sets welding machine and 20,000 m geolock for aquaculture farm project since 2018 in Sri Lanka. Sri Lanka is an island country in the Indian Ocean, at the southern tip of the South Asian subcontinent, close to the equator. Sri Lanka almost stays in summer all year round, and it has only the rainy season and the dry season, without four seasons. It belongs to a tropical monsoon climate with an average annual temperature of 28℃.S ri Lanka’s arable land area is about 4 million hectares and accounting for 61% of the country’s land area, of which nearly 2 million hectares have been used .Sri Lanka’s fisheries are roughly composed of four parts, like coastal and offshore fisheries, offshore and deep-sea fisheries, inland fisheries and aquaculture in coastal areas. The main products are Japanese mackerel, black body, bonito and yellowfin tuna, etc. The main export products are farmed shrimp, lobster, crab, finned fish and ornamental fish.

Sri Lanka’s fish and aquatic products are best sale in the global market. At present, Sri Lanka’s export volume is still unable to meet the global market demand. Therefore, the government has taken corresponding measures to start the fisheries development plan including development of grouper like finfish, catfish and other finfish, implementation of aquatic resources development plan, development of marine fish, ornamental fish, seawater, paddy fish farming, Vannamei shrimp Industry.

Characteristics of Geomembrana HDPE Liner

The aquaculture farm industry runs in a collective mode. BPM Geomembrana HDPE liner is the ideal anti-seepage material in aquaculture farm project. It is conceivable that there are definitely many residues in the water body and the water quality is necessarily bad. In order to prevent this phenomenon, geomembrane HDPE liner is laid around the pond to block some dirt. The anti-seepage performance and excellent long-term performance for geomembrana HDPE liner can protect groundwater resources from pollution. Therefore, in the field of aquaculture farm, the application of geomembrana HDPE liner is also more extensive. The application of geomembrane HDPE liner in the aquaculture industry can have a good protection effect.

- Geomembrana HDPE liner can deal with the dirt in the pool and has the characteristics of good tensile resistance, impact resistance, tear resistance and high hydrostatic resistance.

- Geomembrana HDPE liner has outstanding effects in acid and alkali corrosion resistance, anti-microbial corrosion and anti-seepage.

- Geomembrana HDPE liner can cut off the spread of virus and play a disinfecting role.

- Geomembrana HDPE liner reduces the cost of breeding.

In short, geomembrana HDPE liner is absolutely necessary basement material for aquaculture farm project.

As the leading professional geomembrane manufacturer and wholesaler, The Best Project Material Co., Ltd (BPM) has dedicated to manufacturing and supplying one stop solutions and services to worldwide customers since its foundation in 2010. We have over 120 professional staff and 16,000 square meters manufacturing factory equipped with state of the art production lines. Our innovative, high quality one stop solutions include HDPE geoemembranes, advanced HDPE liner welding machineand professional installation service etc. BPM brand HDPE Liner have been pass the certificates of ISO9001, ISO14001, Soncap, SASO, BV and passed the test of SGS and Intertek etc.

Case Study of Geomembrana HDPE Liner for Aquaculture

BPM client is the leading seafood and the largest vannamei company in Sri Lanka, the client’s vision is to produce seafood with impeccable freshness and quality. BPM client inquired HDPE geoemembane liner and sent us the design drawing for aquaculture farm project. BPM suggested using 100% virgin material geomembrane HDPE liner with thickness of 0.5mm or 0.75mm. Through communication and negotiation, BPM client chose 0.6mm GM 13 standard geomembrana HDPE liner finally. In the meanwhile,BPM showed the its company profile, application cases and professional certificate of HDPE geomembrane liner to clients. BPM shared its geomembrane factory, team and HDPE liner pictures. After our client knew us, BPM sent geomembrana HDPE liner samples to client to test as clients’ request. BPM HDPE geoemembrane liner passed the test, and the client placed the trial order.

BPM Sri Lanka client requested three professional BPM welding workers to install on site for the first batch HDPE liners and taught local worker how to weld geomembrane liner. To save clients’ cost, we told clients the basement surfaces should be at the same level and free of all sharp rocks (all rock and stone greater than .05 diameter), objects, vegetation and stubble. (Soil sterilization may be necessary to kill roots and certain types of grasses.) The subgrade surface should provide a unyielding foundation for the geomembrane line with no sharp or abrupt changes or break in grade. Proper compaction assures stability and support of the liner. If BPM welders came there, even if they did not work, they would be charged per day. So BPM let customers send pictures on site to ensure time and cost savings.

BPM geomembrana HDPE Liner is fabricated into large standard rolls to minimize field seaming. BPM recommended that protective covering of HDPE geomembrana liner not be removed until installation and any uncovered should be stored out of direct sunlight. BPM also offer double-layer woven bags to cover and protect delivered liner rolls.

BPM Geomembrana HDPE Liner for Aquaculture Farm Project in Sri Lanka

BPM Sri Lanka client required 300,000 square meters geomembrana HDPE liner and 10 sets automatic welding machine for whole aquaculture farm project. BPM HDPE geomembrane liner is designed and made of high quality polyethylene resin with proportional carbon black antioxidant, anti-aging and UV-resistance materials which exhibit impermeable and ultraviolet resistance properties. BPM innovative, high quality HDPE geoemembrane liners include smooth geomembrane HDPE liner, textured HDPE liner, composite HDPE liner, etc, which are your best choice for environmental, civil and industrial applications. BPM had provided many types of effective and states of the art geomembranes and other geosythetics to over 81 countries. Our main customers are from Australia, France, Sweden, UK, Hong Kong, Hungary, New Zealand, Poland, Mexico, Ecuador, Brazil, Pakistan, Bangladesh, Thailand, Vietnam, Malaysia, Indonesia, Singapore, Philippines, Sri Lanka, India, UAE, Saudi Arabia, Qatar, Kenya, Ghana, Ethiopia, Somalia, Nigeria, South Africa, Swaziland, Mongolia etc. After detailed communication, BPM client ordered 300,000 square meters of geomembrana HDPE liner with virgin material and GM13 standard for aquaculture farm project.

HDPE geoemembrane liner has been extensively used in some of the largest aquaculture projects in the world, especially shrimp pond and fish pond as the anti seepage lining system. Low permeability, chemical resistance, temperature range, duration of the project and UV exposure are several factors to consider when deciding which type of BPM HDPE liners to use in aquaculture farm projects. BPM geomembrana HDPE liner is the kind of waterproofing material mainly for anti seepage lining system which is made from high density polyethylene raw material with specially formulated, adding color master batch, antioxidant, anti aging and UV resistance component, anti aging agent, antioxidant, ultraviolet absorbent, stabilizer as accessories, etc. What’s more, its anti seepage and isolation performance are strong. All BPM HDPE liner products are in accordance with GRI GM13 and ASTM Standard.

Specifications of HDPE Geomembrana Liner for Aquaculture Farm Project

- Total HDPE geoemembrane liner quantity – 300,000m2

- BPM HDPE geoemembrane liner specification – 0.6 mm

- Each roll size is 7m*420m

- Extra 10 Sets welding machine with automatic operation

BPM Geolock for Aquaculture Farm Project in Sri Lanka

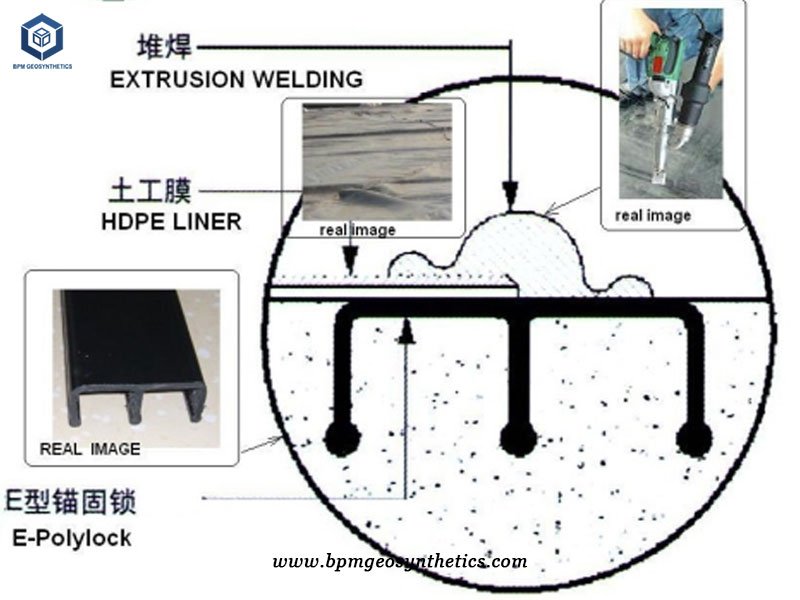

BPM geolock is made from the same resin used in HDPE geomembranes and therefore has excellent UV resistance, low permeability and good overall chemical resistance. BPM geolock is connected to the HDPE liners and concrete is extruded HDPE strip products. E shaped geolock in cross-section is suitable firmly anchored in concrete. BPM geolock is installed in a position reserved for a period of recess when pouring concrete, to be impervious construction of the E type lock embedded in the groove, and pouring concrete forming again, geolock is fixed on the surfaces of buildings and connected with HDPE geomembrane by extrusion welding method. Geolock has the following features.

- Flexible waterproof material with high seepage coefficient.

- Good heat resistance and cold resistance.The temperature of the environment of high temperature 110 oc, low temperature -70.

- Good chemical stability resistant to acid, alkali, oil, corrosion.

- Very high tensile strength.

- Strong weather resistance and strong anti-aging properties so that can maintain the original performance.

- Strong tensile strength and elongation at break.

- Excellent UV stability.

After detailed communication, BPM clientd ordered extra 10,000 meters geolock for the aquaculture farm project.

Specifications of Geolock for Aquaculture Farm Project

- BPM geolock Specifications – BPM15

- Total BPM geolock quantity – 10,000 m

- BPM geolock Expansion size 2.9m

Quality Control of BPM Geomembrana HDPE Liner Products

The aquaculture farm project ordered 0.6mm thickness virgin material in accordance with GRI GM13 standard Geomembrana HDPE liner. BPM factory lab tested 3 times each for shift, three shifts for one day, to make sure the quality is in accordance with the aquaculture farm project design in Sri Lanka. BPM guaranteed the HDPE geomembrana liner products shall meet the 100% virgin material HDPE liners that quality same as sample BPM sent to clients. At the same time, BPM also passed the test for this batch HDPE geomembrane liner from the third part SGS. As the project request, the HDPE geomembrana goods delivered by five shipments.

Onsite Installation of BPM HDPE Liner and Geolock

Crab climbing out of the farm ponds is the problem that the installation process should be overcome. Sri Lanka client hoped BPM engineers were on site with one best solution. BPM professional welding engineer suggested on construct a bio security fence around the site to solve crab to climb out . BPM Sri Lanka client wanted to put the PVC pipe every one meter within HDPE geomemnbrane liners for the bio security fence around the site. At the beginning, the hot air welding machine can weld only 70m in one day including the fence. BPM advised that the big pond should be welded and installed first and the fence would be build step by step when the big area finished. With the help of three BPM engineers, one big farm pond was finished with 2 days. Sri Lanks client decided to let one professional welder to stay and train local welding team with the professional welding machine till local welders finishing the next big ponds. Local welders believed they shall be trained by BPM one welder over the period of doing these works. Indeed, BPM welding engineers successfully taught local welding team. At the same time, BPM smooth HDPE geomembrana liner has proven to be far more cost effective, environmentally safe, excellent durable, chemically resistant, fast deployment and easy transportation. BPM clients were very satisfied with our HDPE geomembrane liner products and our profession in the installation process. BPM witnessed this aquaculture farm project in this two years which was finished in November 2019.

BPM professional welding engineers were fortunate to participate in the eighth anniversary celebration of our Sri Lanka client’ s company. Hope our Sri Lanka clients’ company to be the global leader in sustainable and socially responsible aquaculture farm and develop better and better.

About BPM

BPM has been specializing in delivering one stop geosynthetics products and solutions to worldwide customers since its foundation in 2007. BPM had provided many types of effective and state of the art geomembranes, geotextiles, geocells, geosynthetic clay liners (GCLs), drainage boards, geogrids to over 81countries. Our main customers are from Australia, France, Sweden, UK, Hong Kong, Hungary, New Zealand, Poland, Mexico, Ecuador, Brazil, Pakistan, Bangladesh, Thailand, Vietnam, Malaysia, Indonesia, Singapore, Philippines, Sri Lanka, India, UAE, Saudi Arabia, Qatar, Kenya, Ghana, Ethiopia, Somalia, Nigeria, South Africa, Swaziland, Mongolia etc.

BPM is not only manufacturing best quality geosynthetic products but also providing professional design and installation service. OEM, ODM, custom development and fabrication are also available. If you have any questions or inquiries, please fill and submit the following form, we will reply as soon as possible.